It can add a little extra to the work flow, but ever since @WillAdams mentioned probing with a gage pin, I’ve adopted that method. It keeps things consistent; always clean, doesn’t have any cutting edges/tips that wear, safe to handle, and it’s cheap.

Ok, so I cut something smaller that I could get some calipers on.

https://a360.co/30cfY0c

It should be 120x120mm across the centers.

Across the X axis, it is120.35mm and across the Y axis it is 120.65mm. If you see from a previous post, I did adjust the Y steps from 40 to 40.027, but everything measured good via the MikeP caliper test.

This time I used a single flute 278Z because I think I’ve fubar’d both my 201Zs.

Could it “just” be deflection this time ?

(I don’t have access to Fusion right now so I can’t check your toolpaths to see if you used a separate finishing pass). It could be interesting to try that same cut in the softest material you can find and check whether it comes out more precise.

It would also be interesting to cut pieces of various dimensions to figure out if the error is a constant offset (likely deflection or a zeroing inaccurary) or a linear error (likely belt calibration).

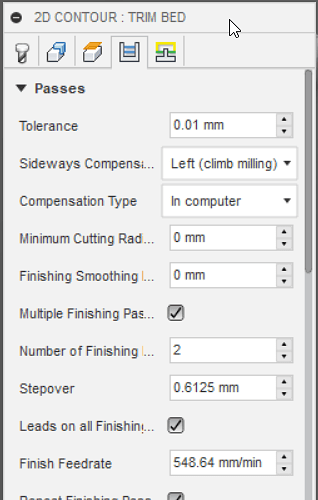

It could indeed be the finishing passes. I was attempting to do 2 passes, full depth. These 2 items, the original 350mm and the 120mm item are the first I’ve played with finishing passes.

From the 120mm item: (With a #278 bit, 1/4" single flute ZRN endmill, 18k RPM)

Before I cut out the 120mm part, I did ensure my steps were good. For something unrelated, I’m going to change out some v-wheels, so I’ll be re-tensioning belts. I’ll be sure to check my steps again afterwards.

Edit: The 350mm part was in 9.5mm of aluminum and the 120mm part was in 6.35mm aluminum. I’m wondering if the step over in the finishing pass is way too much? It was throwing some good chips and the router didn’t sound like it was bogged down.

I guess 0.6mm stepover may be a little too much for the last pass, the router would not struggle but the machine could still deflect a bit (you are 0.35mm off so that’s only 0.175mm deflection on each side). The only way to tell as usual is to experiment (either redo this cut at lower stepover in aluminium, or rerun the same cut in something very soft)

Thanks. I didn’t even consider the stepover until you mentioned it. I’ll probably give it a go and see what happens.

I love the videos Winston makes for aluminum feed and speeds, I just wish he included some information on finishing passes. I know it will (like everything CAM I’m learning) depend on a lot of factors, but anything would be nice.

Do you have a recommended feed/speed and stepover for a finishing pass, at least a recommended starting point?

I tend to use 0.25mm stock to leave and let the finishing pass shave that off. Ideally push the feedrate to compensate for chip thinning at that very small stepover but if you are not familiar with that, keep the same feedrate you use for the rest of the cut as a starting point, it should work fine.

One good way to figure out what your roughing and finishing stepovers are really up to, I’ve done this on plywood, particularly when changing bit to compression cutter for final full depth passes and I’m trying to get close joint clearances;

- Run a roughing job with Stock to Leave, use the roughing passes / multiple depths etc.

- Then run a finishing job with Multiple Finishing passes and the smaller stepovers.

- Finally, run the finishing job (derive new operation is the fastest way to get this) with just the finishing pass.

Measurements during those job fragments;

- Measure after the last roughing cut, read some known dimensions off the Fusion model and measure with a caliper, you can figure out what the dimensions should be from the stock to leave

- Measure again after the last finishing stepover, same measurements, these are lower cutting load and should be lower deflection.

- Measure again after the repeat finishing cut, the difference here is the “spring pass” or deflection you saw in the last finishing stepover.

I frequently find that just listening to the repeat finishing pass, even when it’s just part of one finishing toolpath tells me how heavy the engagement is.

HTH

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.