I designed this pocket cutout. I will try to attach a photo of what it actually cut out. my curiousity is to why the randon chatter. I did this same cutout on a test piece and did not have this.

Battery Box.c2d (124 KB)

I designed this pocket cutout. I will try to attach a photo of what it actually cut out. my curiousity is to why the randon chatter. I did this same cutout on a test piece and did not have this.

Battery Box.c2d (124 KB)

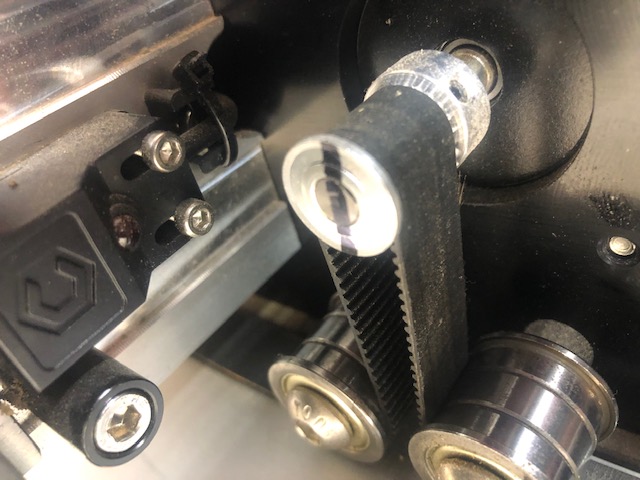

Looks like a mechanical problem. Check belts, also make sure pulleys are tight on the motor shafts.

Belts are tight and everything seems to be in order as I have made many design cuts since this with no issues. machine only a week old.

Is this acrylic? Could be melted plastic due to feedrate being too low and/or too many flutes on the endmill you used. Try feeding faster or using a single flute endmill

In regards to a mechanical issue, this is what I have done. Witness mark to see at a glance

My bet is on chip welding. What are your feeds and speeds numbers?

If this is acrylic, this is what I thought, your feedrate is too low.

45ipm @18000RPM on a 2 flute like the #102 is a 0.00125" chipload, while acrylic likes that in the 0.002"-0.003" range (sometimes more)

I say double your feedrate and retry.

Also, plunge rate is too low. In plastics you want to plunge fast, otherwise while the cutter makes its slow entry into the material, you tend to get melted chips, which can then get stuck in/around the flutes, and can lead to more melting in other places of the cut later.

90ipm feed and 45ipm plunge should work. They key is to always see nice little chips flying while you cut. If you tend to see stringy things rather than well formed chips, your feedrate is probably not fast enough.

The best solution for acrylic though, is to get a sharp O-flute (“O” not “zero”) and dedicated that endmill to cutting plastics only. There’s an Amana kit on the C3D store (here) that has a 1/4" and 1/8" O-flute for plastics, if you cut a lot of that it’s a worthwhile investment.

Hi Julien,

Thanks for the great info, yes it is acrylic. I will check into the O-flute Amana kit as I do a lot of acrylic work. Curious though, as I am cutting both acrylic and wood, will the O-flute work on the wood or will I need to measure the acrylic and set a different toolpath with a different tool after the acrylic is cleared out?

I would recommend you dedicate the O-flute to cutting plastics only, so that they don’t wear too quickly. They will cut wood of course, but will become dull faster then, and as you need a super sharp cutter to get great cuts in plastics, it’s not a good idea and it’s well worth the effort of a tool change/extra toolpath to use separate endmills for separate materials

I just order the O-flute cutters. Thank you for the information. I will measure the amount of acrylic that I have atop the wood and only use these to remove that and the regular cutters for the wood portion. I will post a pocket once I have done my first with this method.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.