Can you share the .c2d file that produced that simulation and cut?

smaller table 1 of 2.c2d (200 KB)

Your slot is at a slight angle. I would also do the finish cut at 90° parallel to the length of the slot.

smaller table 1 of 2_1D.c2d (152 KB)

Seems you are working awfully hard to do the work of a good bowl bit.

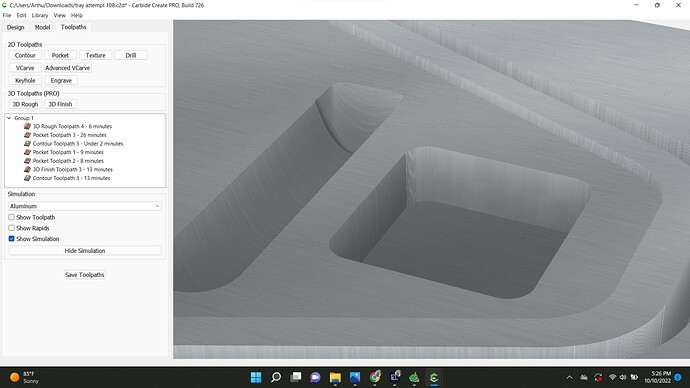

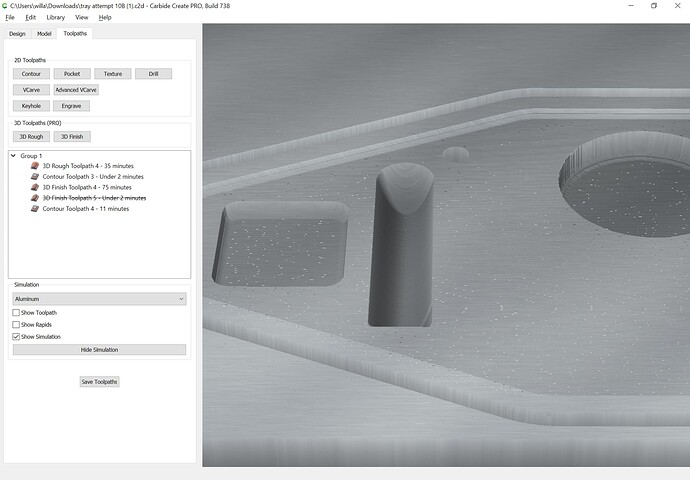

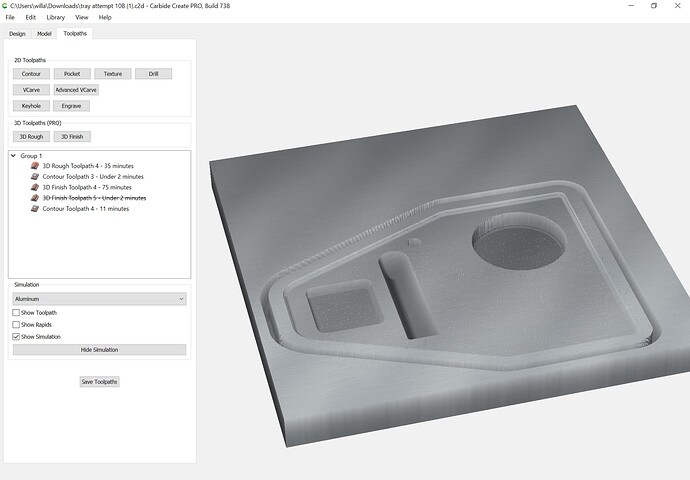

this is the simulation from the file you sent me here. any idea why there is that step in the half round channel there?

sorry im so needy, ill compensate you for your time!

Thanks again!

Post the file so that we can check it?

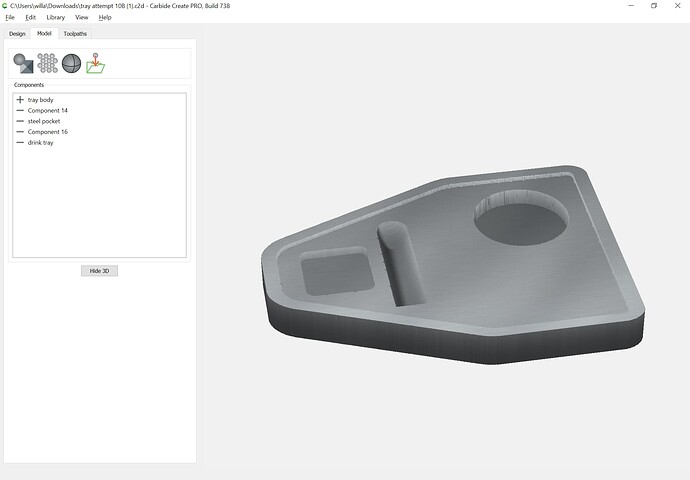

Its the file that ed.e posted earlier. “Trayattempt10b”

The file I sent you back is the same file you linked in your post, with a change only to the finish toolpath stepover setting.

The step in the half round channel may be the result of the channel being very slightly rotated, as @Tod1d noted. It could also be the result of the flat side of the slot not aligned with the rest of the slot, depending on how you modeled it. I think I would model this slot as a rectangle with fillets at both ends just to keep it simple.

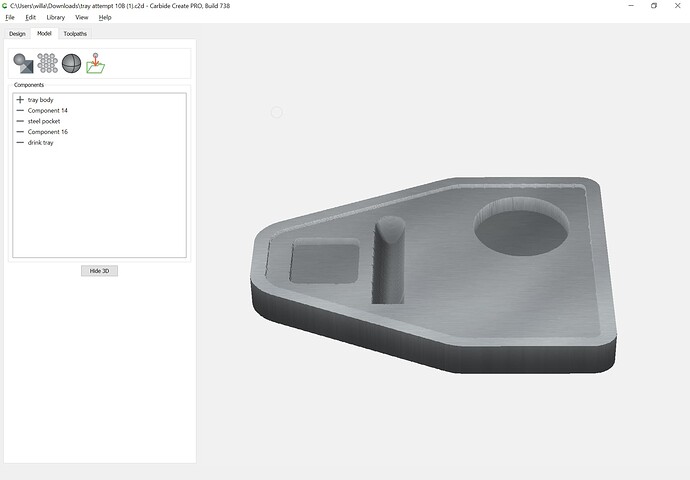

I don’t see it in the 3D model when I set the model resolution to “Very High” and enable “View | High Resolution Simulation”.

except for at certain angles:

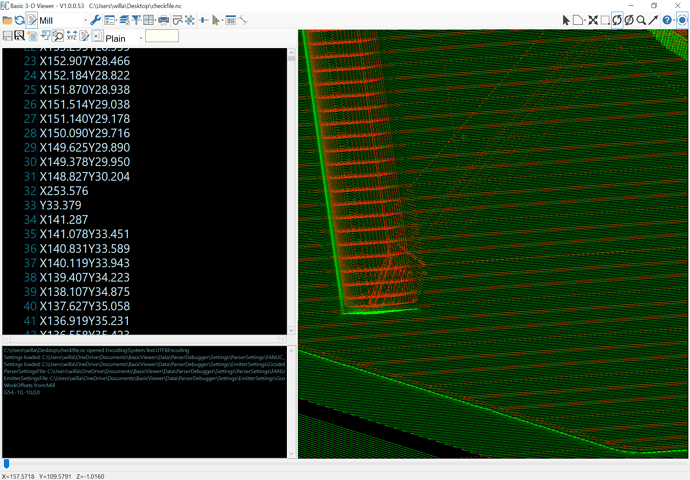

While it seems to show up in the Toolpath view at certain angles:

In the G-code it looks to be an entry/plunge point:

so should cut well so long as there isn’t excessive runout/tool deflection.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.