Cool, book marked it for future, thanks Kenton.

I want to try an engraving bit like these, but they’re all classified as “drag” bits… would you not want the router spinning, and if so what speed?

I think these are “scratching” bits hence the drag name. A burr should be spinning but the drag bits are spring loaded to control the cutting (scratching) force (down pressure) and spinning it in the spindle (imo) would likely break the spring. I’m looking for the proper diamond burr bits for this process and if I find them I’ll advise.

Here’s a drag bit I just found on ebay, don’t know the seller and have not purchased from him ,

http://www.ebay.com/itm/CNC-DRAG-ENGRAVING-TOOL-BIT-SPRING-LOADED-DIAMOND-SHERLINE-TAIG-MILL-TORMACH-BF2-/192237140867?_trksid=p2349526.m2548.l4275

Also saw “drillman” on ebay has router 1/4" shanked diamond burr bits, with so many referring Drillman, I will buy from him when I’m ready.

Indeed I get the process, but I’m asking about spinning the bit vs. not. There’s potential for things to bind or grind if the bit doesn’t turn but everything else is rotating.

I’m looking for anecdotal experiences

No experience, but the link @GeerGuy posted had spring loaded ball mills that you use while spinning. Used for uneven surfaces.

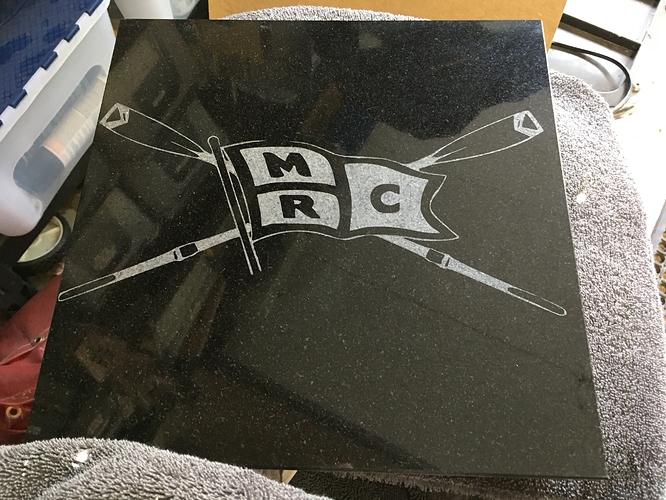

Cut time was < 30 minutes.

Stepover .0050, 70" feed, .0001" stock to leave on a roughing pass only. Used a spring type diamond engraver.

Will center it better next time

Here’s the tool: http://benchtopprecision.com/diamond-drag-engraving-tool/ (Same one @geerguy) posted.

You do not spin this type.

Thanks your video prompted me to purchase drag bit and my first engraving on granite tile was also a Texas seal, very happy with the result…

TX_sgt I see that you are located in Texas and you use vcarve. If you dont mind could you tell me where you got your diamond drag bit.

Is this doable in CC? Or any of the other free tools? I might be able to spring $70 for the bit, but $350 is way more than I can do atm.

I have done it in CC.

It makes CC run really slow because of the tight tool paths, but it can be done.

Dan

Inkscape. Fusion360.

Thx guys! Y’all are the best

great work

Is that water you are using for the cutting fluid??

Great work. I’ve got a blank piece waiting for time and musing!

Would you mind sharing your feeds, stepover, etc?

I got mine from Widgetworks.

Yes, and the water is only used to keep the dust down, and cool the diamond. The speeds probably aren’t

fast enough to generate much heat, but the water also adds a bit of lubricity.

TX_SGT What size was your Texas Seal?