I’m used to doing CAD, but I’ve never done CAM in F360. I watched a tutorial about using the 2D contour, but for the life of me, I can’t get F360 to allow me to select a contour! I’ve got to be missing something obvious, but I don’t know what. Can anyone take a look and help? Thank you.f360.zip (260.4 KB)

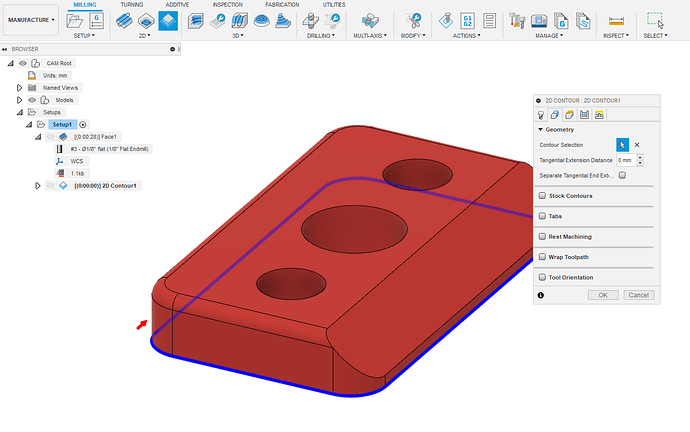

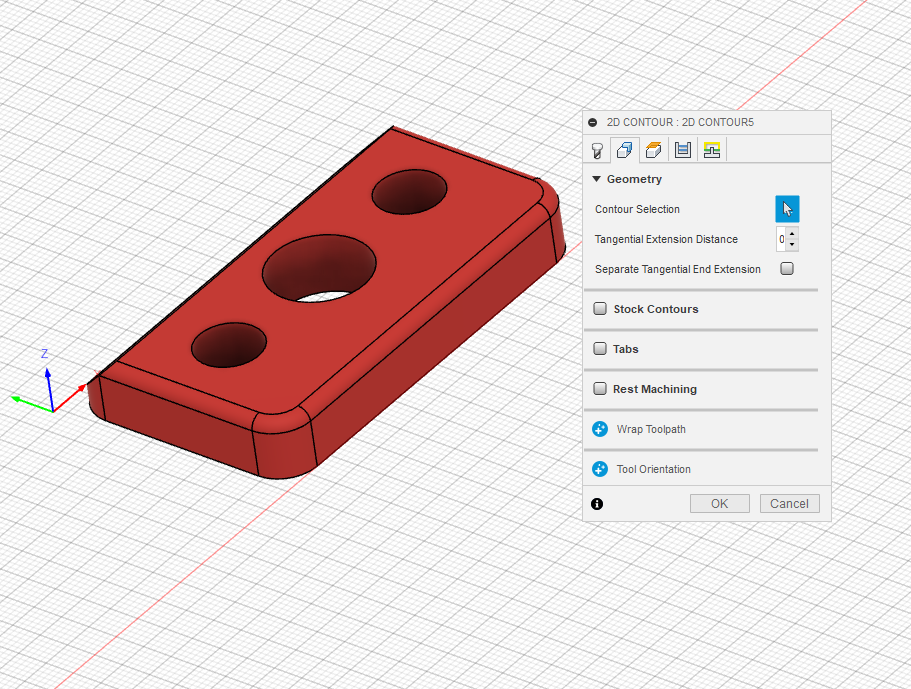

You mean that when creating a 2D contour toolpath, Fusion360 won’t let you select a contour like this ?

Correct! How did you do that? When I click on the little arrow to select my geometry, nothing happens. I think that I’m in the same window as you. But nothing lights up when I move my arrow to select the the contour.

Weird…I don’t do anything special, the edges/contours just light up automatically here

Does this happen for any project or just that one ?

Hmm. Let me try. Would it have anything to do with my free subscription vs paid?

Nope, I’m not a paid user either (and it would be really unusable for free users if it was that  )

)

I’m looking into the various display options/preferences right now, to see if I find any clue.

I’m on version 2.0.9442, yours looks slightly different. what version is it ?

Mine is 2.0.9440. Maybe I should upgrade?

Honestly, this is a very basic F360 behavior that has been there forever, I highly doubt they would have messed up v9440 that much. Still googling…this is puzzling.

I suppose restarting Fusion and creating a dummy project from scratch yields the same result/problem ?

Ok, that was weird. All I did was re-start F360 and it works fine now. I should have thought of that first- always seems to fix electronics in the house.

Thank you!

Ok, so my next question is…which endmills would I need for this part? I’m still learning so I’m sorry if this is a dumb question. Do I need a ball end?

What’s the material?

Ideally, aluminum. It’s for a bracket on a 3d printer. I’d like to expand my CNC skills while also building a printer.

For aluminium, my goto bits are single-flute ZrN-coated cutters, at least for roughing.

Also, I don’t like having to use multiple tools when it is not necessary, so for that relatively small piece which that has two holes smaller than 1/4", I would use an 1/8" single flute like the #274Z

Then for the finishing to get those rounded edges done, a 1/4" ballnose should do.

Living the dream of using machines to build machines, there is something oddly satisfying in doing that, right ? ![]()

Yes you’re right! It’s like a Terminator movie.

Also, I could have the parts 3d printed by someone else, but I thought it would be a good time to learn how to do 3d machining on my Shapeoko. I’ve only ever done 2.5D. I’ve got a Z plus and Zrn bits, so why not try?

Be sure to check the first two vids in that thread, for tips on cutting aluminium with single-flutes:

Thanks!

I guess the final question would be, for these types of basic brackets, could they be made from 60601 sheet? They don’t need to be Mic6, right?

No.

6061 will be fine. Didn’t you say they could be 3d printed?

Yes, they could technically be 3d printed. Most everyone else is doing it that way. They’re making them from ABS since it’s an enclosed printer with higher temps.