yep mine is a pro as well.

I got in contact with support and we are going to try a new driver board and possibly motor is out of spec.

do you have an aluminum or brass pulley?

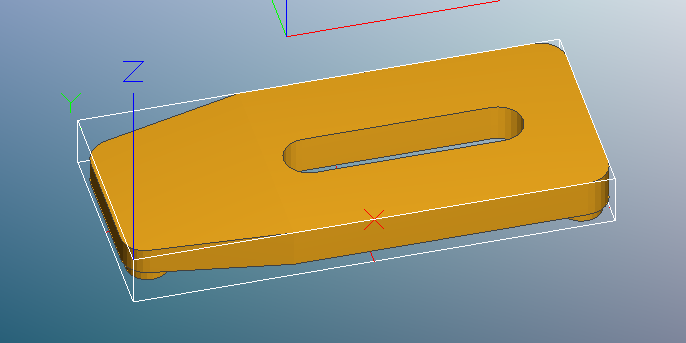

this is one of the most simple parts I stall on. I am able to finish it if my plunge is <.5 ipm

I’ve had a lot more success plunging with a ballnose cutter than a flat endmill. Maybe it’s because the surface contact area is applied more gradually? The flat cutter works well if you can perform your z-axis moves off of the work piece and come in from the side. Aluminum 3D Contouring

I am not sure and I am unable to check, but I think mine is aluminum. I have never seen any brass parts on mine. The plunge rate seems really slow. I plunge at 5-6 ipm. Probably contacting Carbide3D is the best to do.

@Remmy I’ve read that it’s always good to gradually start the cut, so it would make sense ballnose cutters do better while plunging. Thanks for letting us know!

@Remmy that makes sense, looking at your tps from the other thread, id say you are pretty close to what I was trying, the main difference was im using a flat endmill for roughing and often on the plunge the spindle stalls… probably due to 100% tool engagement. only way I found to keep it spinning is by using a painfully slow plunge like .5 ipm even then sometimes it can catch when clearing a corner.