Sweet. Plug it in and experiment.

Maybe you can start a service.

Hmm, maybe I should.

I have three of those RC car bodies still.

They were painted in the late 80’s and early 90’s, the PC(Lexan©®™) is all scratched up on the outside from racing, but not one speck of paint has flaked off.

BTW to clarify, the paint goes on the inside of the body shell, for those who did not know.

I wondered about that given the violent nature of some of those races.

So the 30d Vee did a nice job. I went a little deep but since i cant paint it maybe it helps to see it. Thanks for all the feedback.

This was my first plastics design and first time feeling like i used the machine to invent something.

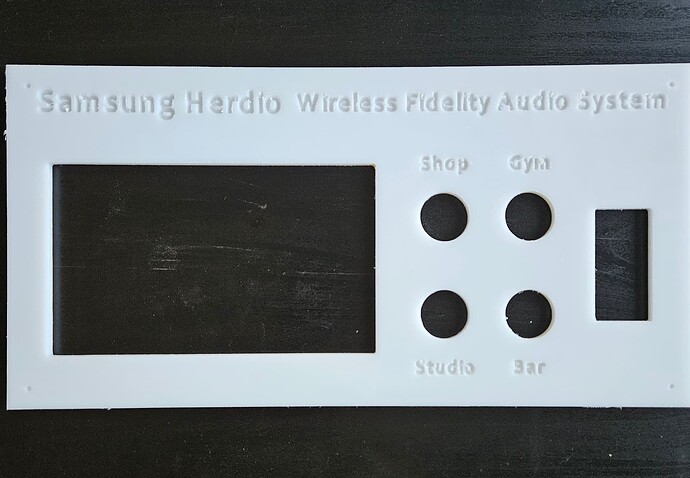

My bluetooth/wifi sterio system has 4 speakers on a single main control and no isolation. Used the S5 to make a control panel to house the tablet and isolation rocker switches for the 4 speakers.

(Powered through the front for testing)

That would probably be a really good use case for that color core stuff.

…go on please…(color core)

Something like this:

I have not tried them but I know others on the forum have.

It would be a neat idea to stack a bunch of 1/8" colored boards and design something based on the layered colors. I get you could do each singularly and attach but it would be neat to see as a pre made stack. Then some of the colors might mix depending on precision of depth across the stock

There are specialty plywoods made thus, and ages ago there was a nifty video on YouTube showing a 3D terrain model being cut in such.

Alright people i need to know this for fixing my current mistake with HDPE…

Hdpe cut for sign lettering already…

If i pocket a piece of wood, insert the lettering, would i be able to pour a clear coat of resin (i know it doesnt stick) over the project and essentially trap the lettering in the wood?

Or is there another solution to using these letters?

They are considered scrap now basically but such a waste not to use them. 8" height.

I was thinking maybe a nice piece of wood with a groove along the width and placing the letters upright, free standing…thoughts? Perhaps back lite

One sign maker I knew would cut such letters, use a screw to attach loops of wire to their back, then use additional screws to secure the letters in place using the wires — with a bit of paint over the wire and screws, the letters seemed to float in place at a distance and were quite secure and didn’t have the obvious defects of through holes.

The material is 1/4"

What screws would be best?

Pointed or flat and pre-drill?

Always pre-drill.

You’ll need to scale the pointy screws to match the thickness and to be careful not to damage the surface either with the drilled hole, or the installed hardware.

That’s thin for screws. Where is the sign going?

I’ve used that nano tape / alien tape stuff to stick HDPE to a painted cinderblock wall that nothing else sticks to. Not something I would give away or put outside, but good enough for holding it in place.

There are a lot of plastics out there being wasted. I wanted to start making things out of recycled HDPE plastics and other types that I can make into blanks. What I have come up with is a way to make the plastic blanks by cleaning and cutting up the HDPE plastic into smaller pieces that get placed into a wooden form and then pressed to remove all air pockets. After it cools down it solidifies. Then it can be cut to size and used.

Mixing different colors gives these neat color combinations.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.