I’ve upgraded my stock Nomad as much as I can without making irreversible changes and now I’ve hit the limits, but I still want some of that sweet, sweet rigidity and accuracy, so I’ve decided to allow the Nomad to reproduce. It’s been eyeing some of the Aluminium extrusion residing in its room and I think their offspring would have promise.

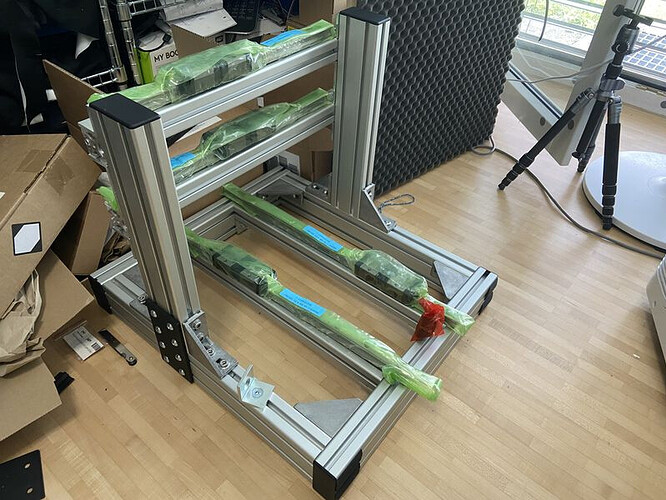

The result so far is this:

40x80mm extrusions for the square base and for the X-gantry supports, 40x40mm extrusions for the X and Y axes. 25mm linear rails for the X and Y axes and there will be 1605 C5 ballscrews for those as well.

I’m intending to use the current Nomad to square the ends of the extrusions and perhaps flatten them a bit if necessary, as well as to machine some rigid, high-precision joining plates and flat plates to mount the rails to.

But the question I’m asking myself is now that I can, should I try to increase the precision of the machine?

I can buy linear scales with 0.1µm resolution and ±3µm accuracy for ~$120 a piece. I can buy Delta A3 servos + drives + cables for $378 per axis. So I can upgrade to a full closed-loop system (rotary encoder on the shaft, linear scale on the carriage) with 3µm accuracy for ~$500 per axis. It doesn’t even require anything fancy from the controller, since the servo drive can handle the linear encoders. It’s just a really accurate step/dir system. Even GRBL could run this.

But would this actually help, over just using bog-standard steppers?

With steppers, my numbers are:

- 1605 ballscrews (so 5mm per revolution)

- ±5% no-load angular accuracy from the stepper itself

- 200 steps from the stepper

- So a single step is 5/200 = 0.025mm ±0.00125mm, or 25µm, ±1.25µm. Lets just turn the step resolution into a range and we’ve got total precision of ±13.25µm.

Microstepping is a thing but it’s by no means reliable.

In addition to the steppers, there’s inaccuracy in the ballscrew. I’m using a C5 ballscrew with ~400mm travel, which corresponds to a further ~27µm of inaccuracy.

So with the stepper system, I’m looking at accuracy of ~±40.25µm, or ±0.04025mm, or about ±1.6 thou. Repeatability should be substantially better.

With the servo + scales system, I should be limited by the accuracy of the linear scale and the servo driver’s ability to hug it, so ±3µm plus whatever error the servo driver introduces. I’ve heard that a servo driver can usually stay within around 10 increments, so with a 0.1µm resolution scale, there should be no extra error introduced by the servo.

The scale should also eliminate most mechanical error, like radial/axial play in whichever coupling I use (e.g. a belt reduction on the servo).

The remaining error would be flex in the frame itself. But since I’m using Aluminium extrusions now, it should be relatively simple to reinforce the frame as needed.

Does anyone have any thoughts or comments on whether this might work?

I should add that I don’t need this. At this point my hobby has basically turned into building CNC machines so I’m not looking to actually mill parts with ±3µm tolerances and sell them or anything, I’m just looking to learn about CNC technology and closed-loop motion control. I want to see how far I can get and which barrier I run into (e.g. maybe I’ll have to start water cooling the frame to minimize thermal variance).

I’ll also add that this is more than a little bit off topic but hey, Shapeoko folks might be interested in this since you could potentially add linear scales and servos to a Shapeoko (particularly pro).

Nomad folks might also be interested in using the Nomad to build another CNC machine the way I am.