I’m using Fusion 360 (v 2.0.6670) and generating gcode via the Carbide 3D post processor (11/2/2019 version). Executing using UGS on my Shapeoko.

The code includes multiple G28 return-to-home commands. This means the bit starts at the WCS origin, moves to the MCS origin, moves back to the stock to start milling, finishes milling, and then moves back to the MCS origin. This is a lot of unnecessary movement. It also has the spinning bit traversing the rest of the wasteboard, possibly intersecting with a clamp.

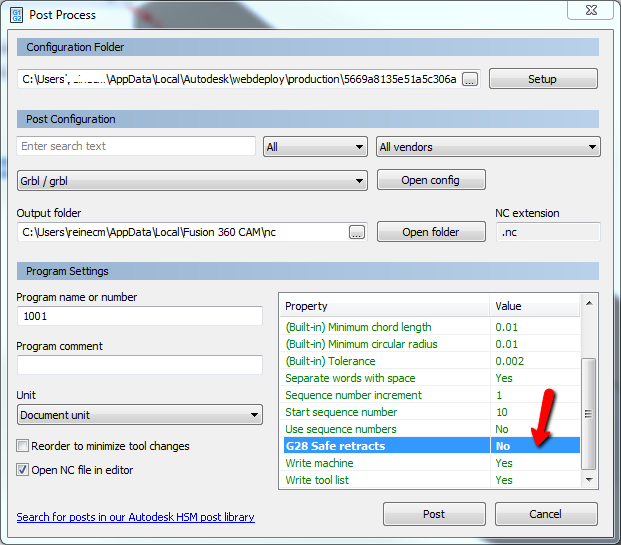

Is there a way to turn off the homing commands without manually deleting them from the code? Or is there a post processor anyone can recommend that doesn’t include the homing cycles?

Here is some of the generated code with my comments:

%

(1001)

(T1 D=12.7 CR=0 - ZMIN=-1 - flat end mill)

G90 absolute distance mode

G17 select the X_Y plane

G21 unit selection - mm

G28 G91 Z0 return to home; relative distance mode; raise z axis 0 mm?

G90 absolute distance mode

(Face1)

T1 M6 This also gives an error in UGS

S17000 M3

G54 work offset (sets WCS origin?)

G0 X30.255 Y-17.21 rapid move to WCS origin offset

Z15

Z5

G1 Z0.27 F1000

G18 G3 X28.985 Z-1 I-1.27 K0

…

G18 G2 X23.27 Z0.27 I0 K1.27

G0 Z15 move to Z-axis WCS origin + 15mm

G17 select the X_Y plane

G28 G91 Z0 return to home; relative distance mode;

raise z axis 0mm Unnecessary command?

G90 absolute distance mode

G28 G91 X0 Y0 return to home; relative distance mode;

X axis + 0mm, Y axis + 0mm - unnecessary?

G90 absolute distance mode

M30

%

I’m in grbl 0.9. I’ll do the upgrade to 1.1. I am absolutely amazed that you could find this info, and almost instantly. How in the world did you find it? My searches turned up nothing.

I’m in grbl 0.9. I’ll do the upgrade to 1.1. I am absolutely amazed that you could find this info, and almost instantly. How in the world did you find it? My searches turned up nothing.