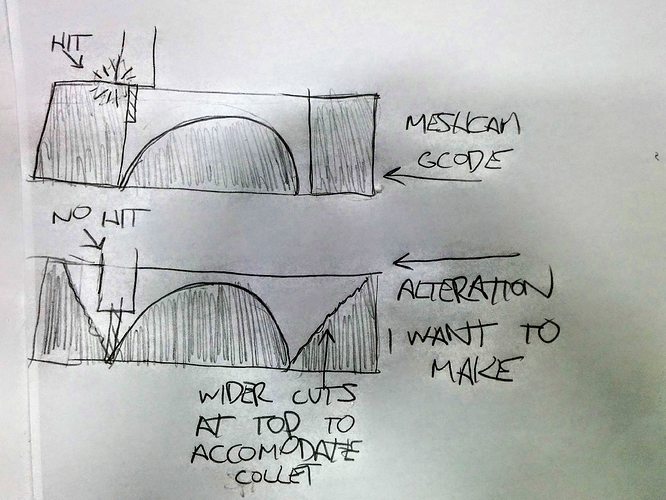

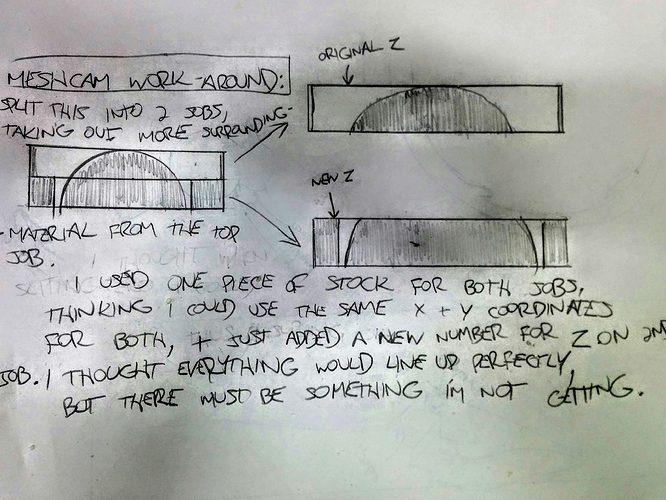

So, I’m just making a simple sphere, around 2.75" in diameter. The plan was to make two halves and then glue them together. As I went along though, it occurred to me that I will be exceeding the flute length/cutting length of my cutter. I’m using the #101 .125" ball nose cutter that came with the machine. Meshcam gave me a gcode that looked fine at first, but it doesn’t seem to take into account the depth limits of the cutter. After trying unsuccessfully to figure out a way for meshcam to cut out enough material at the top of the stock surrounding the part to clear the way for the cutter to reach the full 1 3/8" to the bottom, I decided to slice the part into two jobs: I’d cut out a lot surrounding the part on the top half, and just do the minimum on the bottom. I was concerned that I wouldn’t line the two jobs up precisely and this would create a noticeable seam, but then I figured if I just determine the new Z coordinate for the bottom half, I could just re-use the X and Y numbers I had for the top half, right? This would put me in the exact same spot as before. I just typed in the same numbers for X and Y at the set zero page in meshcam, confident that this would work… but no go. The cutter promptly began gouging the newly cut top of the sphere when I started the bottom half job.

I have a number of questions about this exercise: first, is this really as severe a limitations as it would appear? I took for granted that I could put a piece of stock in this machine and get full 3" Z cuts out of one job; hence the name ‘Nomad 883’. I’m sure this is indeed the case and I’m just flailing right now, so please someone, tell me how to do this!  It seems like I should be able to cut out extra material surrounding the part in a pattern that narrows toward the bottom so that it clears the way for the shank as I go down, but I couldn’t figure out a way to do that. Also, I’m dying to know why my plan to re-use the X and Y coordinates didn’t work.

It seems like I should be able to cut out extra material surrounding the part in a pattern that narrows toward the bottom so that it clears the way for the shank as I go down, but I couldn’t figure out a way to do that. Also, I’m dying to know why my plan to re-use the X and Y coordinates didn’t work.