On the Shapeoko Pro XXL has anyone made modifications to the waste board? Like a fence, cam clamps or dog stop holes?

I’ll be doing a new spoilboard this weekend for my 4XXL, as long as UPS can find my house today with the inserts I ordered. I did make a terrible set of cam clamps out of 1/4 in plywood. They work very well at work holding, but they are like me, ugly but functional

I was just curious.

Wanted to know if it is a good thing to make grid lines on the inserts, or, to go with dog holes for squaring and work holding?

Can also use dog holes for cam clamping.

I cant make up my mind which way to go.

I haven’t made modifications to the track/waste board yet, but I’ve been experimenting with a few different options using the track. I have a corner square that mostly stays square — I need to beef it up a bit.

I also designed some little cam clamps that work well for clamping along the y axis. They can be small, because the t-track allows you to get them right up against the workpiece before you start tightening.

Clamping along the x axis is trickier, because it needs to span up to the width of the t track gap — I’m thinking of designing something similar to this: https://www.rockler.com/kreg-in-line-dog-hole-clamp

I’m using the corner square Carbide 3D sells but any could work or you could even make your own thanks to the magic of CNC.

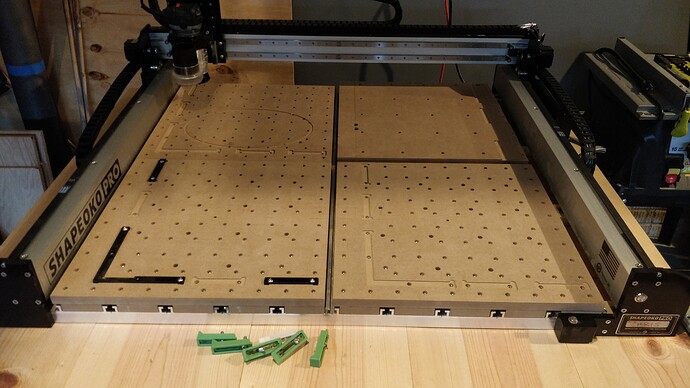

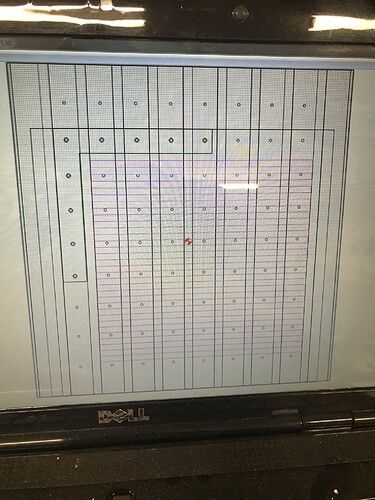

I pocketed a groove for the square to sit in. This helps to ensure everything gets screwed down perfectly aligned in regards to each other. I have the waste board mounted to the table using t-nuts. This makes it easy to adjust, move, or remove as needed. I’ve done my board in four sections so things can be adjusted as needed or replaced easily. It’s also because I buy my MDF in 2x4 sheets since I don’t have a truck to transport full sheets.

To perfectly square the board with the machine is simple. Just leave the wasteboard mounting screws a little loose, jog the endmill to the origin and drag it against the square along the x-axis to perfectly square with the machine. Use an old bit so you don’t damage a good one. When things are squared tighten down.

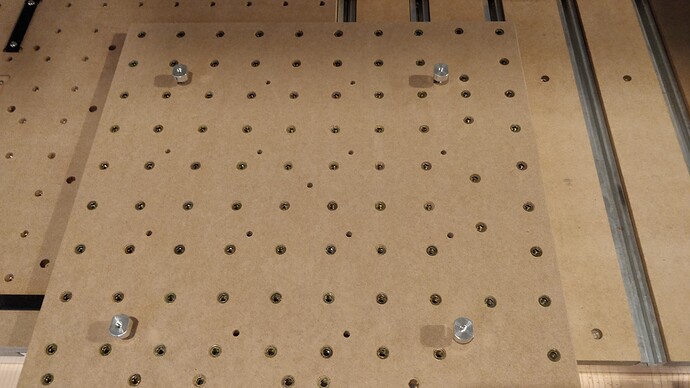

I’m also in the school of thought that you cannot have too many anchor/clamp locations. 50mm spacing has been working well for me.

Awesome work. Would you consider sharing the design files with the rest of us?

Super simple MDA fence… had the machine drill the holes for the inserts in the waste-board slats of MDF. Then used some scrap NDF I had laying around to cut out the fence with the same threaded insert hole alignment. I plan on installing threaded inserts throughout the table at some point but I got busy doing other things.

Sure! Sorry it took a bit, I was on vacation toward the end of last week. Here’s a thingiverse link, let me know if you have any questions or issues printing the models: https://www.thingiverse.com/thing:4902391

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.