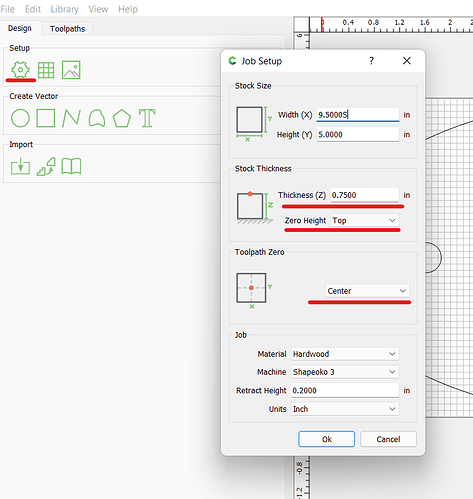

Open the file in Carbide Create and confirm a couple of settings. From the main window with nothing selected click the gear in the top left corner. Then check the thickness of the material and make sure it is set correctly. Next check that the zero height is measured against where you are expecting. If you are measuring against the top but the file is set to bottom or vise versa you will have issues with the Z depth, like plunging into the stock or carving above the material. Also confirm your toolpath zero is set. My example shows setting against center but you can select something else. Just make sure you set it properly when you set them in Carbide Motion.

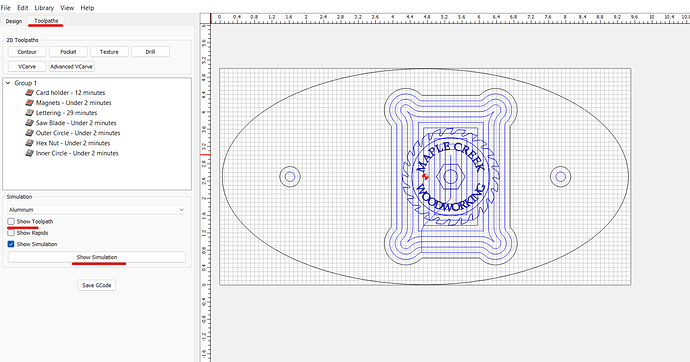

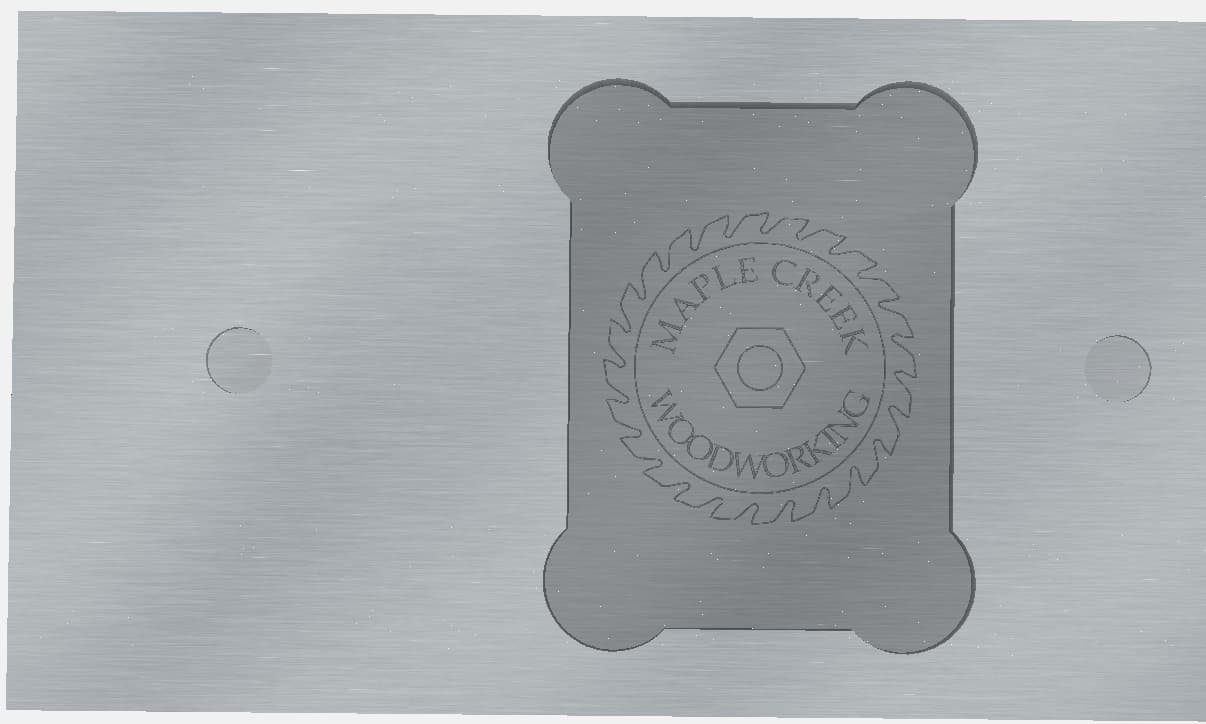

I like to measure off the top but I know that others prefer the bottom. It will really depend on your workflow that you start to develop. Once you have those confirmed go to the toolpaths tab and check the preview. Does it look right? You may want to uncheck the option to show toolpaths so you can see the project instead of a bunch of lines showing where the machine will move.

This will show you something like this but obviously for your project.

Once you like the way it looks, click save Gcode and name the file appropriately. You can now go to Carbide Motion and Initialize the machine. As it initializes, it will prompt for a bit. Put in the bit you want at this point and let it check the height. Once that has done move the machine using the rapid positioning and the manual jogging to the zero points you set above. If it is center and top like my example, move the bit to the center of the material and the top of the material. Then you can set the X, Y and Z zeros. I can’t get screenshots right now since I have a job running. This has directions to help you get the zeros set. Just make sure you follow the zeros you set in Carbide Create.

The next thing that you will do is load the new Gcode that you created and start the job. It will prompt to put in the first bit and move to the front center. If needed, change the bit and if not just click continue. It will move to the bitsetter and check z against the new bit. It will then move back to the front center. Here is where I used to do something manually to check the Z height since I had a lot of similar problems when I was starting. I would put a straight edge across the top center of the material and run it out to where the bit was sitting at the front of the machine. I would then run a ruler from the bottom of the bit to the bottom of the straight edged and check the screen in the Carbide Motion software. The left hand side has the Z location of the bit currently. This check would need to match the ruler. Make note this is always in millimeters so you need a ruler with mm or you need to convert. This saved me so much material at first. I would do this check after every bit change.

After a while I was sure I had the process down and no longer run the above checks but it really helped me understand how the machine was working and saved me a lot of false starts with either carving above the material or worse plunging into it. I hope this helps get a better understanding of the process and how the zeros need to be set and at least for a while, double checked.