Absolutely, I couldn’t agree more. I’ve been so happy the last month, almost like I was given another chance. Better yet, they sent me a new cartridge free of charge once they tested it and determined it was set off due to skin contact (not metal or wet wood). I didn’t know that, but it sounds like that’s standard. They were really great to work with.

Thats right i totally forgot about the free cartridges for blood letting.

Unfortunately (or fortunately) the majority of cartridges set off at our club are set off by careless types who don’t like rules… or thought… we make them pay for those cartridges.

No wet wood, don’t lean a plywood panel by your truck in the snow and then try to cut it… or how about putting an aluminum mitre guide in the wrong mitre slot and using it like a sled and ramming it into the blade (how, what !??) the nicks in the mitre guide are very small which shows how fast the brake engages…

It is definitely tough to choose where to start, so many options and not sure what you are actually going to need.

Lots of good advice so far. A couple of things I agree sound particularly useful in your case are a track saw and a good sanding solution which should include either dust collection or a plan to sand outdoors. If you decide not to get a table saw at first then a miter saw will be really useful. I started the other way around and used a table saw with various miter gauges and jigs for years before getting a miter saw.

I either missed or did not see mention of type of lumber you think you will use. Track saw is great for sheet goods and as mentioned by others can joint an edge pretty well, but this assumes the lumber has a flat surface to reference. If the lumber is rough you need a way to joint and plane a flat surface. Small pieces you could do on the CNC similar to facing a spoilboard. Beyond that you either need some hand tools and lot of labor or a power jointer and planer.

You asked specifically about power tools but I recommend a number of hand tools that will always be useful. I started long ago wanting to work with rough lumber. What worked for me was a very stout traditional workbench and a collection of hand planes and saws. I bootstrapped using the hand tools and an improvised workbench to build a proper workbench. Scrub, jack, jointer, smoothing and block planes can do a lot but are labor intensive. For me the labor was therapeutic, but I can see that others may not enjoy it.

For joinery a good dovetail saw and Japanese style pull saw work great, along with a set of bench chisels. The CNC may work for some joinery but in furniture making I think you will run into many cases where you will want or need these basic hand tools.

You will also need some type of stones for sharpening the hand tool blades.

At this point I have a large collection of stationary and portable power tools. I still use the above hand tools for something on almost every project.

On the subject of power tools, I did not see anyone mention drill bits yet. A good set of forstner and brad point bits are very useful. Besides the obvious utility of making round holes these can be used to hog out material when making joinery such as mortises.

To address one more specific question, I rarely find a use for a portable circular saw on “nice” projects. It is just not accurate enough and you end up spending a lot of time to clean up you cuts. The track saw is a different animal in that it can be quite accurate. I build homes and to me the circular saw is almost exclusively used for cutting framing materials. Anything that will be seen in a final product gets cut with something that will be more accurate and/or leave a better finish.

Thank you for your detailed feedback. I’ll definitely need to acquire a set of hand tools in my wood working arsenal, this will probably be part of round #2 along with the cabinet saw that I know I will get, just not right now to manage budget.

All:

By the way I just noticed that Festool now sells table saws with the SawStop technology, now sure if they have licensed it or partnered or bought them or something. When I’m ready to drop $4000 on a cabinet saw, I’ll have my eyes on their models.

In the meantime, I’m in the final phase of selecting my track saw, just went to check them out at the store and the Bosch (Blue/pro line) sure looks like a good candidate.

Festool bought Sawstop.

Just an fyi: the makita track and the festool tracks can be used with each others saws…

Also if you plan on cutting sheet goods regularly you may want to consider both a short track and a long track. Or you can get joiners for two short tracks. But it is nice to have the long track so you can switch without taking the tracks apart.

And one more tracksaw tip. If you are breaking down lots of sheets (like making cabinet boxes or bookshelves) a 4x8 piece of sacrificial xps (foam board) on any flat surface makes it really painless to make all your cuts…

This is a cool idea for a cutting table:

You mentioned pull saws, so while we are talking tools, and I feel everyone is giving honest opinions (vs YouTube sponsor and amazon affiliate links  )…I do not have a Japanese or any other type of pull saw, and I’ve recently discovered from watching way too many woodworking YouTube videos, how useful they are. So any suggestions on which one I should buy (Chicago based so HD, Menards, Lowe’s, Amazon, etc), and not looking to blow my bank account.

)…I do not have a Japanese or any other type of pull saw, and I’ve recently discovered from watching way too many woodworking YouTube videos, how useful they are. So any suggestions on which one I should buy (Chicago based so HD, Menards, Lowe’s, Amazon, etc), and not looking to blow my bank account.

Also, is one enough, or do I need two types?

I’m no expert, but I like the “ryoba” style over the “dozuki” ones, and I find the Japanese pull saws vastly easier to use than western push saws (which says more about my abilities than it does about western-style saws, but I do think Japanese saws are easier to use). The lack of a stiff metal spine on the ryoba means you can cut all the way through thicker stock, and it has both rip and crosscut blades depending on what you’re cutting. If I did more small precise work like dovetails I’d probably get more use out of the dozuki, but the ryoba is a terrific all-purpose saw - it can cut thick hardwood easily and it can also work as a flush cut saw.

I bought a random one off amazon years ago that works well (https://www.amazon.com/gp/product/B078HR8Q7X/), but I also hear good things about the Suizan brand. Pricing seems pretty consistently around $30 (the one I linked has an extra blade) so I wouldn’t spend much more than that, though you could probably find them cheaper elsewhere.

I also use a ryoba style pull saw and it did very well for about two years, now I need a replacement blade (20€). As long as the blade is sharp, cutting is almost effortless.

There are also versions with short blades (15 cm) that are great for cutting tabs, for example. I got a cheap one off the local hardware store, but it wore off quicky. So I guess investing in a good brand is well worth it. Especially if you can get cheaper replacement blades later.

I’m also really clumsy with my hands but the way you operate the pull saw definitely supports you in achieving straight cuts.

Oh, and following up on @RichardS mentioning stones for sharpening.

I once found a plane with a perfectly dull plane iron in a cellar. It was so dull, you could measure the radius of the cutting edge with the naked eye.

Since that plane was probably used by my grandfather or even grand grandfather (who was a carpenter), I decided to sharpen it and bought this guy. It took me three hours or so of sharpening, but the plane iron is now fully functional again. That sharpening stone also rescued some old kitchen knives, so it is not only valuable in theworkshop.

I have large and medium double sided Shark Saw brand pull saws which can be found on amazon. I have been through a couple of replacement blades over the years but have not tried another brand. These work for me but I’m sure you can get better quality. This is something I should explore, have not thought about it lately.

I also have a few of the small single sided pull saws from Harbor Freight. They are cheap and nice to have around for cuts that might not want to use a “nice” blade on. For example cutting tabs on a plywood or plastic CNC project.

If it is not immediately obvious the design breaks down in minutes.

Thus ::

The parts consist of two folding sawhorses, two 8’ 2 x 4’s and four 4’ 2 x 4’s

The 2 x 4’s interlock with half lap joints.

Bill

This thread keeps on giving, this is excellent and I will steal this idea, thank you!

I was scratching my head on floor planning to fit a 2.5m x 1.2m table somewhere for the occasional work on large sheets of MDF/ply, but this will be a much more flexible solution.

I finally broke down and bought my first Mafell tool (the quick change spindle: https://www.timberwolftools.com/mafell-fm-1000-ws-milling-motor — also picked up a step up/down transformer and some collets — if the 6mm collet doesn’t work for 1/4" tooling I’ll have to have one made at Elaire).

and in the course of researching it came across this thread:

https://www.festoolownersgroup.com/festool-tool-reviews/mafelll-vs-festool-(-and-others!)/

which has me wanting a matching jigsaw and drill/driver and drilling station and eventually a track saw and duo doweler (or maybe a Domino) …

You mentioned this model before and I must admit if I had not upgraded to a spindle already I would have given it some serious thought, that quick change mechanism looks great, you’ll be able tell us if it works as good as it looks!

I suppose going down the Mafell road is a oneway ticket, once you have had a taste of luxury it will be difficult to come back to “regular” brands ![]()

Yeah, but it seems it’s more complex than just branding and colour-coding:

which brings us back to a link/graphic I’ve noted before:

I’ve seen this before, and also one done for the food industry, which is quite alarming in some ways.

I like little old Makita sitting there, a lone wolf looking after just itself…

Awesome router - Next Project for Will - design the perfect router mount to work with the spindle that enables the quick change feature

I’ve gotten it drawn up — seems pretty straight-forward — the further issue will of course be dust collection.

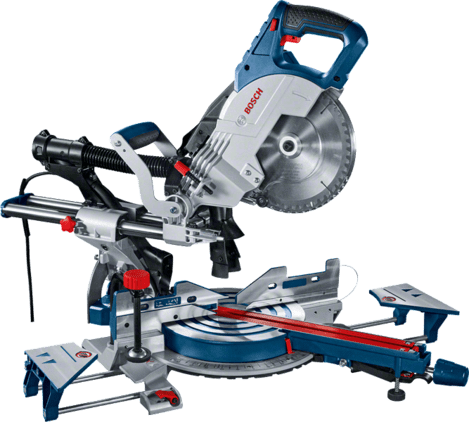

So I’m now part of team Blue apparently, those two are on their way:

I’ll report after I have had a chance to test them. The rest of the list will have to wait!

Thanks again for everyone’s insights.

Those two tools will take you far. They are not a shop full of tools but you can do more than you think with a Track Saw and a Compound Miter Saw. If you have not had a Chop Saw they make a terrible mess. If you have a space you will use it in mostly make a box for it to sit in and contain the mess. The Compound Miter Saw (Chop Saw) are also finger removers. So please pay attention with a chop saw and make yourself hold downs for short work. Never get your finger within the danger zone. The danger zone is basically the whole length of the table. I know that seems like a lot of real estate but a chop saw can give you the nick name STUMPY real quick.

Check out this youtube video for a hold down, there are many more similar. https://www.youtube.com/watch?v=SUoBF8rtrRg