The BitSetter should be configured per:

https://carbide3d.com/hub/courses/running-shapeoko/configuring-bitsetter/

At that point, it should work to measure the tool length offset of any tool which is used, and instances where it does not are either an issue with the electronics/connection (check in with support) or a disconnect between how the origin is specified in the job:

https://carbide3d.com/hub/courses/create/job-setup/

and how the zero is set relative to the stock:

https://carbide3d.com/hub/courses/running-shapeoko/movements-zeroing/

I find that opening the .c2d file up and drawing a box which matches the specified dimensions (draw up the cut in profile if need be) or moving the machine to the origin and then using a tape measure to measure out the dimension(s) in question will make clear where things aren’t lining up.

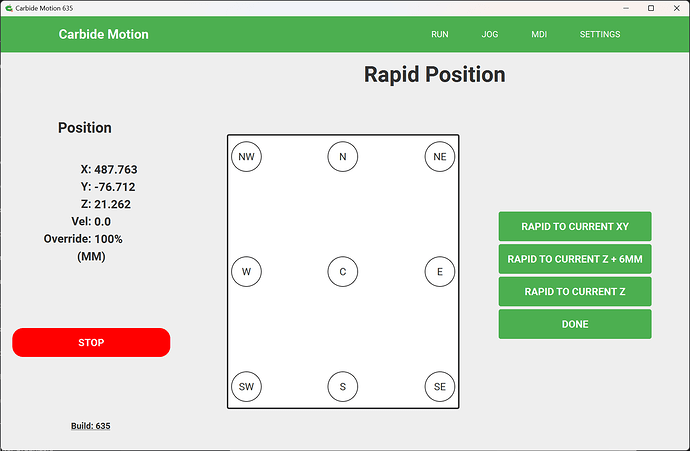

Note that you can use the Rapid Position commands:

- Rapid to Current XY

- Rapid to Current Z (or Z+6mm)

to verify that the BitSetter measured accurately (which brings us full circle)