do i use the pocket tab ? I’m confused on which setting can someone help?

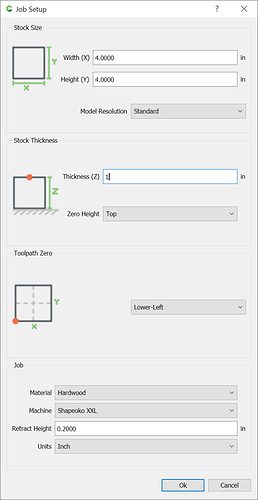

Start with a suitable stock thickness:

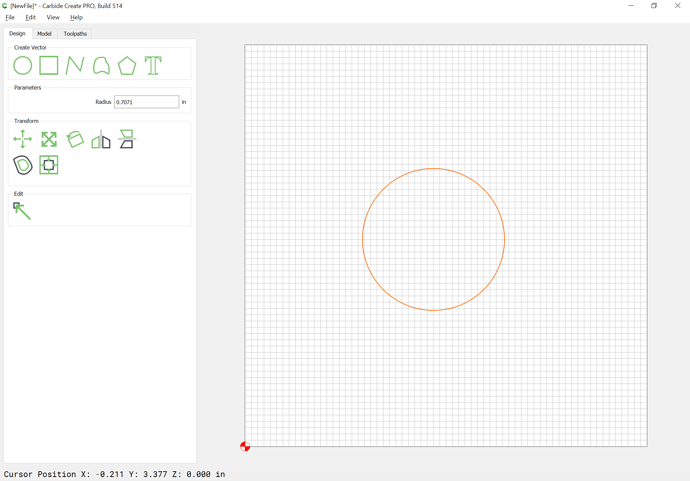

Draw a suitable geometry:

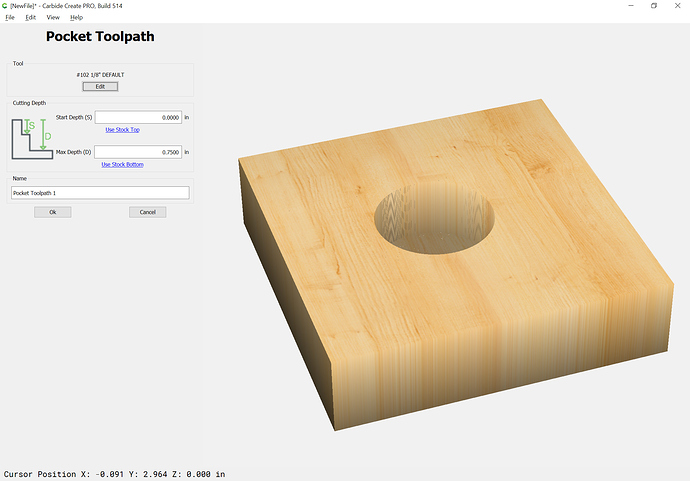

Assign a Pocket toolpath less deep than the geometry is thick:

can i use a forstner bit

Not in a trim router.

You should only use tooling which is rated for the RPMs which trim routers (or your spindle) spin at and which have a cutting geometry which matches your toolpaths — most CAM tools expect to be able to plunge, so the endmill/router bit must be center cutting.

See:

ok so the 201 bit that came with the machine is what i should use

and i need to set the stepover

Yes, the #201 is fine — stepover should be set to whatever is appropriate for your material and your finish expectations.

This topic was automatically closed after 30 days. New replies are no longer allowed.