A friend needed some custom business cards. In this tutorial I’ll show you how to complete this using a laser (3 Watt NDB7875) and v carve pro. I used version 6.

The specific laser is a 3 watt from Objectworks.co’s Kickstarter campaign, though this would work with 2.8W jtechphotonic’s kit as well.

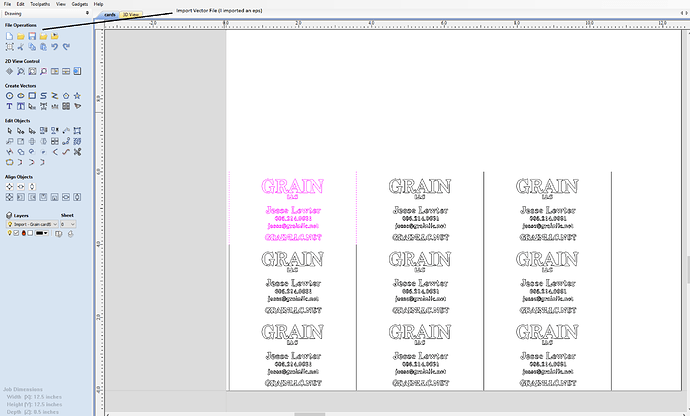

The first step is to get your artwork into v carve pro.

Once imported you can duplicate the card design to cut multiple at once. Gather card stock for etching. I was provided with 12" long pieces which were 1.98" wide and .044" thick. I taped them together in a line so the laser did not need to cut out the horizontal line.

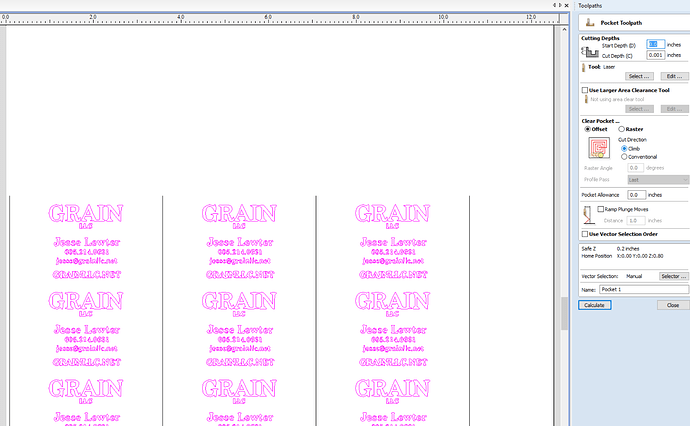

Expand the toolpath window, on the right side and click on the create a pocket toolpath button.

Select the vectors to engrave. Set cut depth to .001"

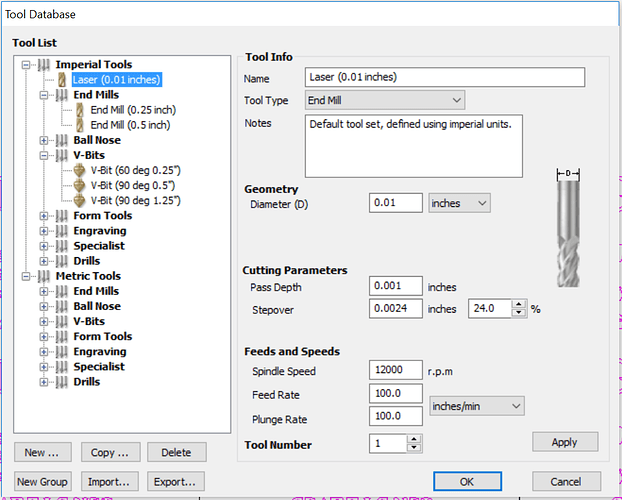

Click on Select … to select a tool. You will need to click on new and create a new tool much like this picture. The spindle speed and feed rate will change depending on if your laser is more or less power then what I’m using.

If using the Carbide3d firmware on your machine, set Spindle Speed to 6000, Feed Rate 110in/min, and Plunge Rate to 100in/min for engraving 1mm thick walnut.

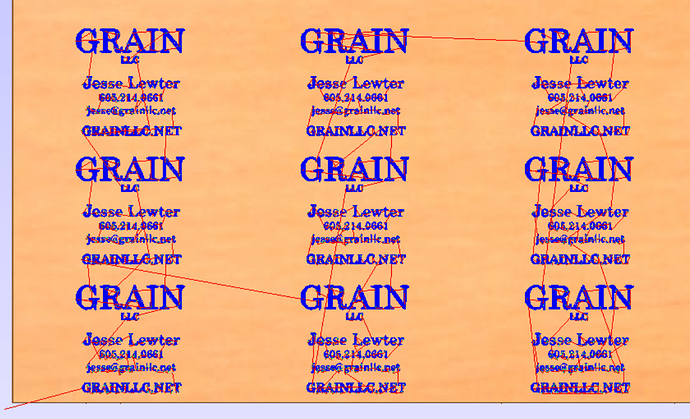

Once you have this set, you can click calculate and view the generated gcode.

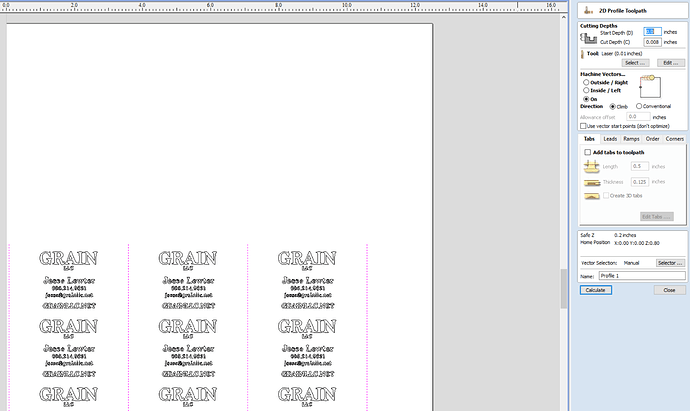

Looking good, now let’s generate the code to cut the cards out. Create a 2d Profile toolpath and select our lines. Set the Cut Depth to .008". Choose the laser tool. Set Spindle Speed to 15,000, Feed Rate to 13in/min, and Plunge Rate to 100in/min. Because in the tool we set pass depth to 0.001" we know it will run 8 passes for the cutout. 8 Passes at this feed leaves a nice line, without too much burning. Too Fast = not cutting. Too Slow = Burning Be SMART, have a fire extinguisher nearby

The next step is to export the gcode. I will not go into how to install the post processor for our Carbide3d machines as there is already a very good reference here.

Then just run the code. I used bCNC, but am guessing any sending program should work fine.

Notice how just the vertical lines are the only cutting element. With this type of setup it is much slower going then a 40W or larger laser. For instance this whole run of 9 cards takes 1 hour and 1 minute. Try and do cutting other ways.

Apply some danish oil, and admire your handywork.