So, to start with a little background. Perusing local ads, I ran across a listing for a Nomad 3 at a really good price. I don’t need another CNC, but I’m a weak person… So this is regarding a used machine- serial number 3040 if that helps…

When I was checking it out, I noticed that the spindle was a little sloppy- enough so that motion could be clearly felt by hand- but I have found another thread on this issue so I think I can sort that out.

The more serious issue was with the Y axis- it had at least .01" of slop. It was a hard stop at each extreme with only slight binding, so it didn’t seem like a worn anti-backlash nut. I flipped the unit on its back and could see that the fixed half of the nut was clearly not tight on the carriage block- so I assumed that it was just a matter of tightening the hardware. So I bought the unit and took it home and snuck it into the house.

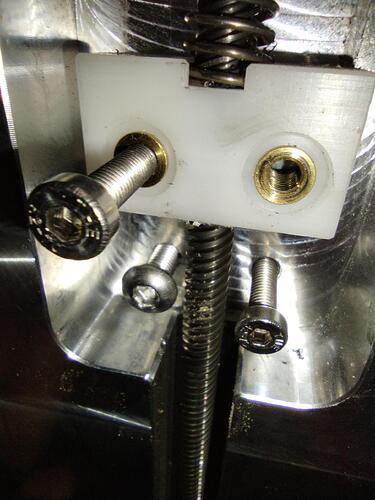

However, on closer inspection, the issue was not as simple as assumed. It turns out that the nut was not actually attached to the block. The nut has threaded brass M5 inserts- but the block has M6 tapped holes. The two M5 cap screws were threaded through the nut, but were simply loos in the holes in the block- hence the slop. (The attached picture shows the nut and block, with both M5 and M6 hardware for comparison.)

The fix I can see is to remove the entire anti-backlash nut and reverse it, as the other half does not have the inserts. Proper M6 hardware could then be used to secure it.

My question- is this a known issue? Is there something I am missing? Is there a different fix I should be considering?

Thanks in advance.