Hi @Angelo

As @WillAdams has described, the radius of the tool must be considered when preparing art for the CNC inlay workflow.

By considering the size of the tool you will use you can make sure your parts will fit perfectly together.

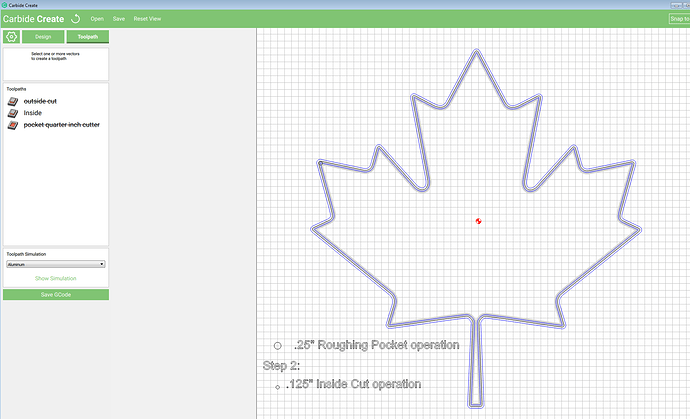

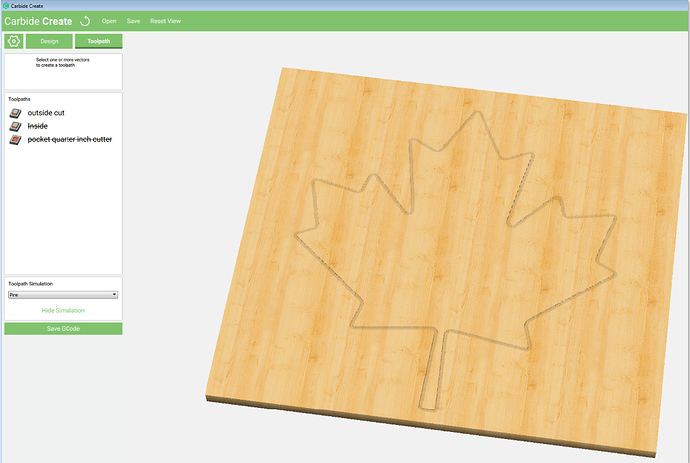

Take a look at this test file; I have added a radius to the sharpe corners to allow for a .125" cutter to define both the inside and outside of the shape.

maple leaf adjusted for inlay.c2d (270.9 KB)

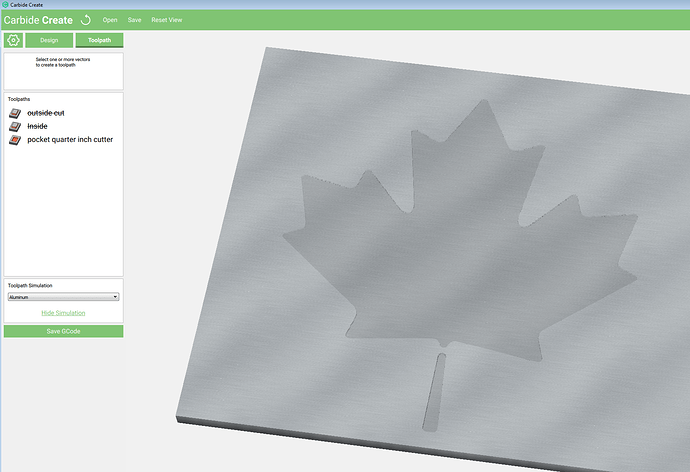

For this Maple leaf example it will take 3 toolpaths and 2 tools (#201 .25" endmill and #102 .125 endmill).

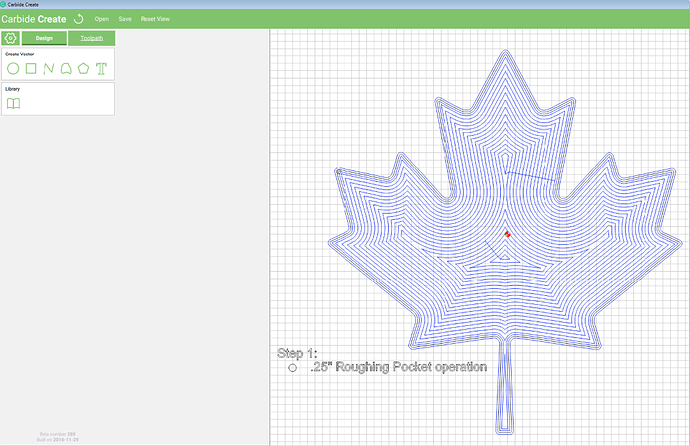

Step :1 “Pocket” cut with a large tool, like the .25" endmil.

Heres a look at the result of the Pocket cut with the .25" - you can see that the tool cant reach all the areas, and a smaller cutter will be needed.

Step 2: Use a “Inside” the line style toolpath with the .125" endmill to reach the perimeter details.

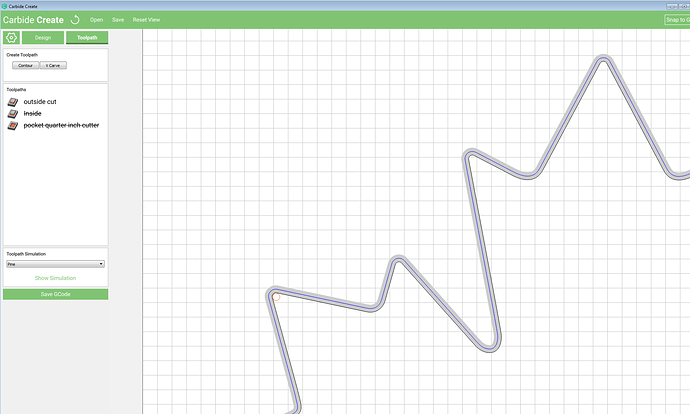

Step 3: Use a “Outside” toolpath to cut the inlay material.

If you have to scale the Maple leaf down, you will need to use a third tool, smaller than .125" and a third “inside” cut toolpath.

-Apollo