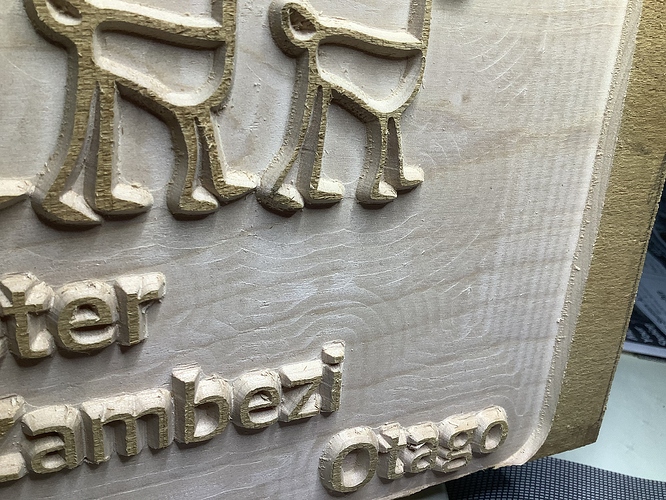

Hi All,Just needs some experts to comment about the surface finish I am getting.Using advanced v carve,.25 Endmill and the wood is silver beech.I have squared router up but have not touched the rails.Any comments would be really appreciated this may be the normal?

Hi @Graham,

Marks like those are usually at least partially due to imperfect tramming of the router. When you say you “squared” the router up", what exactly did you do and how ?

There are a variety of methods to tram the router, from using a bent coat hanger to fancy tramming devices. My take on this here

And then…some types of wood are just less forgiving than others and will show subtle tool marks even on a perfectly trammed machine. I’m not sure about silver beech. I’m confident you should be able to at least reduce those marks significantly by adjusting the tramming (front/back seems to be the priority based on that picture)

Thanks Julien,all I did was attach a piece of wood to the bit and the other end had a nail that was my reference,it was very close all the way around the 360 degrees.I will try the square in the morning.One other thing could it be my Mikita router as at the number 3 setting and either side of it it is making one heck of a noise and could be vibrating up the z axis.If I speed up or slow right down it disappears???I need to try that.

Sometimes a given RPM value associated to a given feedrate and depth of cut will produce a resonance like that (chatter), and just changing the RPM slightly will make it go away.

When you say the router makes a heck of a noise at setting 3, do you mean at the router itself or at the cut (chatter) ? Anyway, I doubt it is directly related to the tool mark you are seeing, but you never know.

Since you already had a go at poor man’s tramming (piece of wood and nail, which is perfectly fine in many cases!), you may want to cut a pocket in some other type of wood to see if you get similar tool marks.

From the picture it would look like (but hard to tell for sure) the router could use a little shimming so that the top of the router rotates slightly towards the back of the machine. You could try and insert a small shim (aluminium foil folded over a couple of times for example, or thin feeler gauge) on the underside of the router mount, between the mount and the plate, and redo the cut to see if things improve.

What I will do is try a few test cuts in MDF and ply before I alter anything.If still the same I will shim as you suggest.

The router noise I thought was from the machine but with the machine turned off and powering up the router after checking brushes it is without question the router.

For the router noise, check the bearings for play — if under warranty contact support@carbide3d.com — they’re easily replaced, see:

https://wiki.shapeoko.com/index.php/RT0701

(The RT0701 uses the same bearings, brushes, collets, &c. as the Carbide Compact Router)

Hi Will,I have the RT0700C,it is way outside a warranty and has had a reasonable use,but I have not checked the specs of the 701 but would they run same bushes and bearings??If so I would get some to top up my order from Carbide.

The machine is so accurate in circles,squares and depth of cut but I will try the test cuts,then shim and then the router??

The RT0700C is the 220V variant of the RT0701 — everything else is the same — we don’t have brushes and bearings in stock for sale, and only the former to provide to folks having warranty issues.