A former colleague of mine is having a farewell party next week, I figured I would try and make something for him, and it would serve as a fun week-end project as well as allow me to double-check my feeds and speeds reference. We go way back, and we have a private joke about a short sound clip from a silly commercial, so I decided to make a musical greeting “card” of sorts.

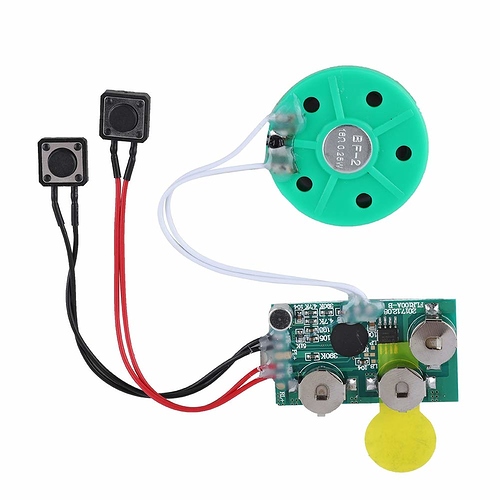

I got this thing on Amazon for about 10$, it has a small battery, a tiny speaker, and electronics to record a few seconds of sound and then replay them when a button is pushed:

I cut a wooden enclosure (well, technically bamboo), cutting a recessed hole for the speaker, a series of 1/8" holes as a speaker grid, and a pocket & hole to fit a push-button under the top surface:

The main pocket and speaker pocket were cleared using a 6mm 2-flute endmill, 15000RPM, 1500mm/min (59"/min), DOC 2.5mm (0.1"), and a 2-flute 1/8" endmill for the pushbutton pocket (15000RPM, 750mm/min, DOC 1.5mm/0.06")

I flipped the part, and drilled the speaker grid holes using the same 2-flute 1/8" endmill, and peck-drilling (not necessary since I only had 2mm of material to go through, but it was the opportunity to use the option in VCarve). Finally, V-carved the top, poured epoxy, let it cure for 24h, surfaced, then a very light sanding:

For the back cover, I initially wanted to hold it with four screws, but I rushed the design a bit and forgot about it until I had finished cutting, epoxying, and sanding the part, so lazy me decided to just cut a cover that would be tight enough that once it was pushed in, it would not come off. So I added two small notches to be able to remove the cover later.

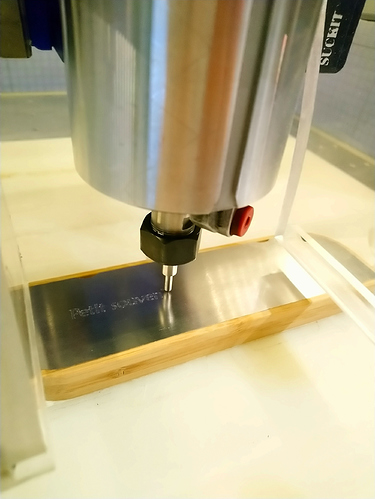

I used some 2mm thick aluminum I had on hand, and cut the cover profile with a 1/8" 2flute ZrN-coated endmill (Carbide3D’s #102-Z), 12.000RPM, 450mm/min (18"/min), DOC 0.3mm (0.012"), ramping + lead-in/lead_out:

I did not feel like using my locline/air compressor, so for this simple cut I decided to just spray a little WD40 across the surface before running the job, and even that was not really necessary.

I had prepared myself to have to cut & adjust this cover a few times to get this to fit just right, but the gods of CNC felt benevolent today, and it was a PERFECT fit on the first try. Oh this feeling…made my day.

The farewell message on the back cover was made with a diamond drag bit

I’m happy I could finish this in time, next week will see the hotest heatwave in France in a long long while, and the temperature in my garage will be unbearable…

Cheers,