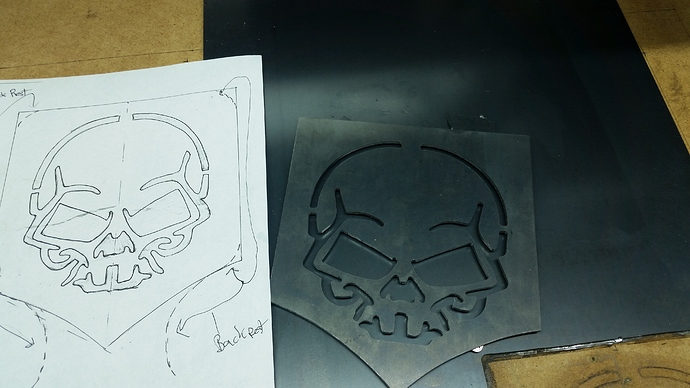

Very cool. Any more details like what type of metal you used, feeds and speeds, end mills?

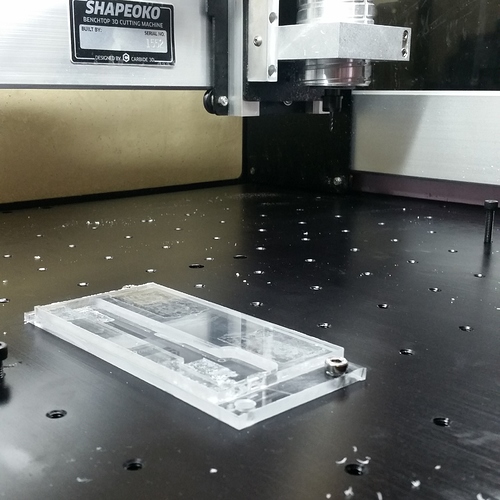

yea i used steel and 6061 aluminum with a 1/8 carbide coated endmill for the aluminum and a 3/16" endmill for thhe steel

These are awesome!

What type of feeds and speeds did you use to cut the steel? What was your depth of cut per pass?

I would be very interested to hear anything that you are willing to share about your process in creating these.

I am going to try my hand at making emblems from 6061 aluminum soon and any advice, feed/speeds, finishing techniques, etc. would be appreciated!

with speeds its a little tricky but what i find works for me is turning ur router down all the way as low as possible down to 16k rpm if i could get it even lower i would but still maintain same torque it would be even better. i personally like to use 1/8 3fl endmillls the seem to be working out better for me. but for my cutting feedrate on the steel i did 8in/min which is pretty slow with a .01 depth of cut and lots of WD-40. for aluminum i like to go 20in/min at .020 in depth of cut and about 18-20k rpm. with again lots of lubricant there are many different ways of ding it but this is what i found working best for me.