Has anyone seen guide lines for speeds and feeds for keyhole bits of various sizes?

I haven’t but my guess is that chip evacuation is the biggest hurdle here ![]()

Intuition says that going with as slow a speed as you can get away with on the spindle would be the thing to try. Idea being that lower speed gives more time for the chip evac and less friction overall.

A well directed air blast may also be more useful with keyholes than regular cuts. Getting the captive chips blown out of the slot seems extra beneficial here ![]()

Should be interesting to see what shakes out of this thread ![]()

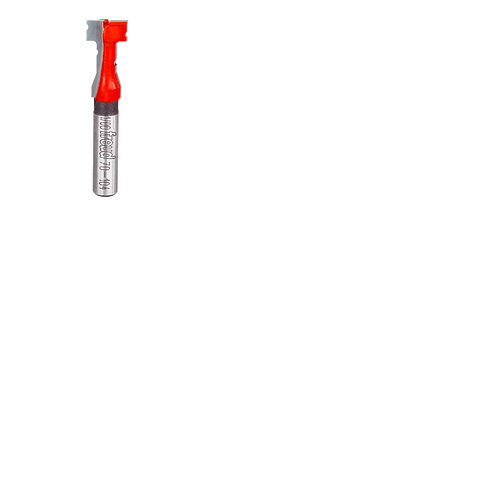

Here is my custom tool for the Freud keyhole bit.

| number | vendor | model | URL | name | type | diameter | cornerradius | flutelength | shaftdiameter | angle | numflutes | stickout | coating | metric | notes | machine | material | plungerate | feedrate | rpm | depth | cutpower | finishallowance | 3dstepover | 3dfeedrate | 3drpm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 701 | Freud | 70-104 | Keyhole | end | 0.39 | 0 | 0.25 | 0 | 0 | 2 | 0.125 | 0 | 10 | 60 | 16000 | 0.4375 | 1 | 0 | 60 | 16000 |

It is specifically for the 70-104 Keyhole Bit. Similar bits would likely work.

Just made some keyholes yesterday.

Those are the settings I use on my Boomerang 3/8 keyhole bit and it startles me every time I use it because it’s loud and fast. I wonder if slowing the feedrate a little bit would help

Yesterday I cut 2 keyholes. I had not cut any in a while. I agree with you that it was startling but it works. Slowing down the feed rate would not really hurt anything. Just dont go so slow you dont get any chips.

Only one way to find out! Good to run tests in pine and maple for example to dial in your F/S’s for keyholes.

Thanks @gdon_2003 I’ll save those numbers. Did you get those numbers from Frued?

Also, do you guys pocket out a hole first for the big end to drop in or just plunge that baby straight in?

I plunge that baby right in ![]()

![]()

I’ve done both, in hardwoods I’ll run a pocket first with a 0.125” up cut then run the keyhole bit. If its a softwood I just run the keyhole bit.

On the tool I provided for the Frued it just plunges in then drives forward, reverses and then comes out the entry hole. It is a very fast operation. In and out.

This topic was automatically closed after 30 days. New replies are no longer allowed.