I use sheathing plywood for the table top ( save $10 ), a little sanding so I don’t get splinters.

It’s going to be covered up with the machine, tools dust and debris anyway.

Particle board comes in a couple styles, use the PB that has finer grain ( sawdust) and treat both side with shellac, when drug sand with some 280 then 220 sand paper. The top coat with poly urethane clear. When dry, lightly sand- This will last and repeal moisture for a long time. Rxman

This might be of interest to you. The first & second pics are what I use on my DWC 4848 big machine (4’x4’, 2500lbs, ATC/Laser, 4th axis, etc).

The second pic is just an example, but very similar of what my machine supplier provided.

Check it every once a while for level, hasn’t moved a mm yet & no issues with the concrete or the Karen next store about noises from the studio keeping her cats awake.

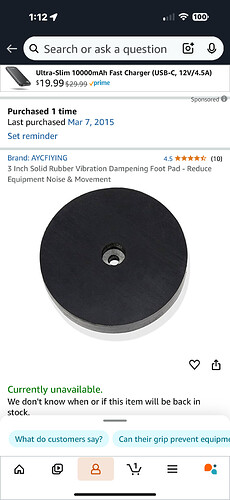

I added the Vibration Pads to stop transmitting the vibrations into the fresh concrete & protection of said concrete.

The smaller Vibration Pads I used on all my Hobby/Pro Hobby machines, currently 5.

I also use either some all drawing board rubber top or the exercise form mats on top of tables for the Hobby machines.

Reasonably cost

I have used a self levelling floor in my workshop and it has been absolutely fine. The secret is to use the right product!

Most self levelling materials are latex based and not designed to be a final wearing surface or even paintable. They are designed to have a wearing surface placed on top of the screed i.e. tiles or wood or LVT, otherwise there is a very real risk of it breaking up.

However some, such as Sikafloor 131 Ultra which I used, are cement based plus latex and can be used as a final wearing surface, and is suitable for vehicular traffic and for use in some external applications.

On my floor, I then applied two coats of gloss epoxy floor resin using a roller, which further seals the floor and protects it from spills, is incredibly tough and easy to clean, and looks fabulous! Just remember to seal the concrete slab before putting the self levelling floor down, or you may get pin holes due to escaping air if there is any porosity in the slab.

My Shapeoko bench has those castors with the adjustable wind down feet. It glides across the epoxy surface of floor very smoothly.

So yes, self levelling floor can be done very successfully, and for me was well worth the effort - just make sure you select the correct product.

I have been looking into those types of casters. They seem the most feasible to me. I also like the foam pads as well. I hadn’t thought about padding my machine to reduce noise and vibration. That is a definite item I will be looking into as well. Have to get past the purchases of the lumber bundles I am currently working on getting. Building up stock material so I don’t have to keep running to the hardware store for any material. I will have it at my fingertips.

This topic was automatically closed after 30 days. New replies are no longer allowed.