I recently bought a VacMaster 16 Gal Shop Vac. During my search for bags and accessories I saw that many ShopVac filters and bags fit the VacMaster. Check out VacMaster to see if they make your fittings. They may make the Shop Vacs or at least some of them. I have an older Craftsman that has the same embossing on the top as the VacMaster and I think they just make vacs for whoever wants them to make them.

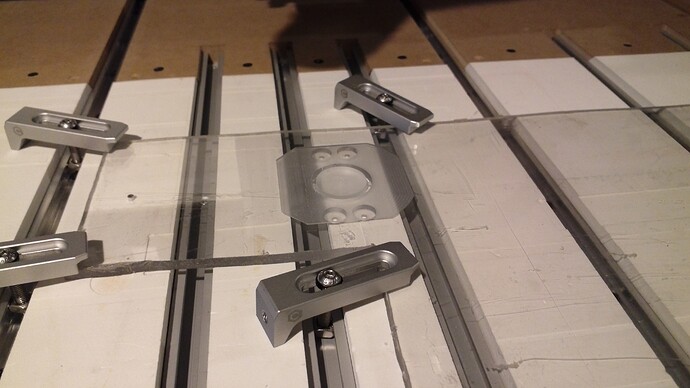

Trying again on the dust plate — just rerunning a pass at the bottom of a pocket in acrylic yields a nice finish w/ minimal cleanup necessary:

In retrospect, probably should have cut the bottom first — hopefully the flip goes well.

Funny how hind sight is always 20/20.

Yeah, better than. Here are the files:

sweepy_adapter_bottom_274.nc (127.1 KB) sweepy_adapter_top_274.nc (223.7 KB) Sweepy adapter_acrylic.c2d (384.5 KB)

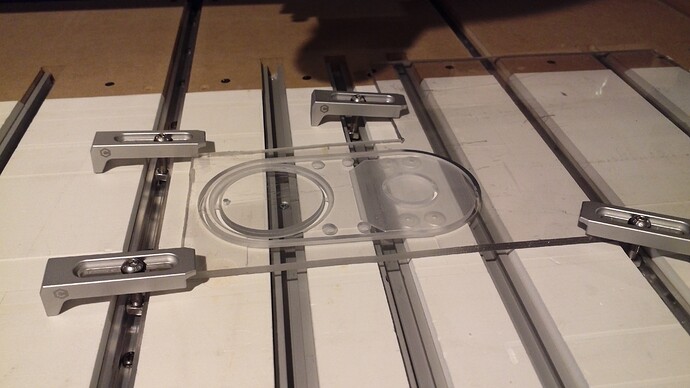

Success:

I’ll need plates of varying thickness for endmills of different lengths, but that will have to wait for sourcing some more hardware.

How much pressure do you have to apply to the lever for bit changes? Is it enough to possibly tweak the Z axis out of tram or is it smooth and easy?

There’s a bit of force involved, but the length of the arm affords a good bit of leverage, and the mechanism itself is wonderfully smooth (made by magical Bavarian elves as noted above), so I don’t anticipate a problem — that’s a good point though, and something I’ll have to work up a test for.

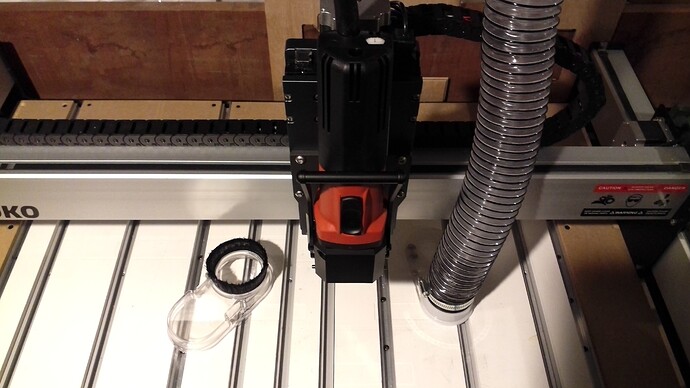

Finally got this installed, so I can report that the action of the tool change is smooth and easy enough that I can swap out an endmill while the power is off w/o moving my HDZ or the gantry at all:

Test cuts tomorrow, then I’ll have to arrange all of the endmills I use, measure the length of their stickout, and work up dust collection options for all of them.

And I have an idea for adjusting the dust collection down for longer endmills:

Shorter endmills are looking to be challenging though — think I’m going to need to take a saw to a Winston bristleless dust shoe bottom…

Lee Valley has a lot of unique products. Everything I have ever gotten from them is first rate.

Agreed. They are a fabulous company, and I’ve never regretted a purchase, nor sending them money.

For folks who aren’t familiar w/ them, here’s a wonderful story on what a great company they are:

A first cut went well:

Just to touch base — I’ve been doing a lot of testing, which has involved a lot of tool changes, and the Mafell Quick Change Spindle has been working perfectly.

Did have one disconnect which I’m attributing to the transformer — hopefully I can get things re-arranged a bit so that it’s not so close to the electronics.

The other consideration is that the Mafell FM 1000 WS version is no longer carried by Timberwolf Tools — apparently it will be replaced by the FM 1000 PV-WS model:

(which brings us full circle)

It would be pretty cool if someone could document what is involved in connecting that to the BitRunner connector on a Carbide Motion board — even cooler if Mafell would work up a 110V unit.

sounds like it has a “0-10V portal control”, so it would probably boil down to procuring the correct set of connectors, and a 0-5 to 0-10V voltage shifter to insert between the bitrunner connector and the portal.

If it’s 0-10V it’s probably analog, and you can get cheap PWM to analog voltage converters from the usual suspects. ( https://www.amazon.ca/Baoblaze-High-quality-Voltage-Converter-0-100/dp/B07CNRWB2C). The ones I got from AliExpress can accept a wide range of PWM input.

You will need to set the min/max spindle speeds, some light unverified googling says $30 and $31 will set this. This will then control the PWM output for a given RPM and “map” it appropriately.

A bit of an update on this.

I was warned when the step-up/down transformer was suggested that it was a heavy-duty unit which could potentially burn a house down (or maybe they meant that no using this could cause that)…

anyway, I usually unplug/turn off the dehumidifier when running the CNC, but the other week I forgot — as near as I can figure, both it, and the spindle came one at the same time, followed by “the magic smoke” and half the outlets in the basement going dead.

Turns out the basement wiring was bridging from one outlet to the next using the outlets to carry the current over, which was too much for the outlet feeding the outlet the dehumidifier was plugged into — burned out the outlet, but the appearance was quite terrifying.

An electrician pretty quickly sorted out, and we scheduled a return trip to wire up half the basement outlets on their own circuit, and to put in a separate 20-amp circuit for the spindle/vacuum — finally got all that done this morning, so back up and running.

Recommendation: if using a spindle which has the potential to make a very heavy current draw, get a separate circuit run for it, and future-proof it by making it 20 amps.

With the 20 amp circuit breaker #12 wire and outlets rated for 20 Amps. 15 amp standard outlets an #14 wire are not rated for a 20 amp load.

This is for US 120 vac.

Yeah, not sure what the step-up/down transformer was actually pulling — hopefully the dedicated circuit will be workable.