Mcmaster-carr does - if you ordered this afternoon or early tomorrow, you’d probably see them tomorrow morning or afternoon (I would in San Diego). More than you’ll ever need, but prices and shipping are usually reasonable.

Gonna ride across the river deep and wide

Ride across the river to the other side

Yep, they’re brits.

That was the first album I ever bought to play on the first turntable I built with the first amp and probably first set of speakers I built.

Youngster! Valve amp? I have some of their LPs too, awesome band (and guitar licks)! ![]()

Indeed, my first amp build was a MOSFET, I always thought valves were best for guitar amp heads… It didn’t take me long to get to Stevie Ray Vaughan from there.

Hardware store didn’t have exactly the hardware I wanted (really miss the local place which closed which had a much better selection), so have ordered from the magical land at the other end of the FedEx route.

Looks like I’m going to need a couple of dust shoes since the design I hacked up isn’t adjustable to account for different lengths of endmill stickout, so I guess it’s back to Lowes to buy another extension wand or two to cut up.

Debating on trying a design which connects to the underside of an HDZ4 which would be static relative the height of the stock.

Go take a look at PWN CNC Dust boot. I think they had their design on thingiverse. That is if you have a 3d printer or know someone that does.

Not wild about how that mounts, and I’d prefer to work up a design which is easily made using the machine, rather than requiring a 3D printer (have yet to get mine back up and running since loaning it out).

Take a look at this one: Dust Shoe for Kress, Mafell, and other (?) Spindles / Milling Motors by nbernard - Thingiverse maybe you can adapt and machine your own. It was the only one on thingiverse that mentioned Mafell.

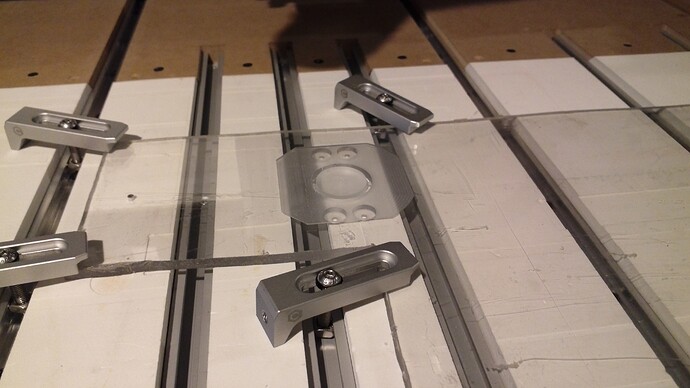

Latest bit of progress is making a vacuum hose adapter:

will finish up the dust shoe for that, then I’ll make a series of adapter plates of various thicknesses which will allow adjusting for different lengths of endmill stickout.

I recently bought a VacMaster 16 Gal Shop Vac. During my search for bags and accessories I saw that many ShopVac filters and bags fit the VacMaster. Check out VacMaster to see if they make your fittings. They may make the Shop Vacs or at least some of them. I have an older Craftsman that has the same embossing on the top as the VacMaster and I think they just make vacs for whoever wants them to make them.

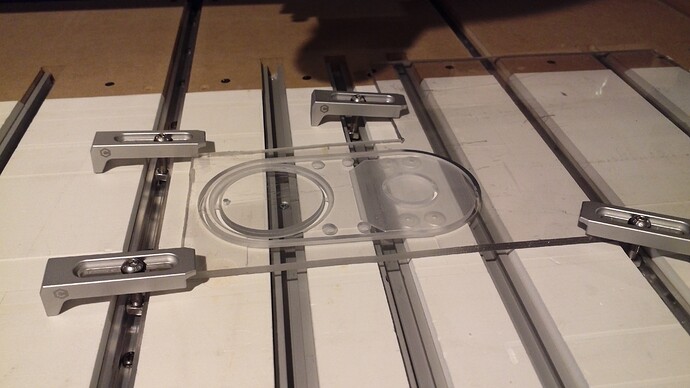

Trying again on the dust plate — just rerunning a pass at the bottom of a pocket in acrylic yields a nice finish w/ minimal cleanup necessary:

In retrospect, probably should have cut the bottom first — hopefully the flip goes well.

Funny how hind sight is always 20/20.

Yeah, better than. Here are the files:

sweepy_adapter_bottom_274.nc (127.1 KB) sweepy_adapter_top_274.nc (223.7 KB) Sweepy adapter_acrylic.c2d (384.5 KB)

Success:

I’ll need plates of varying thickness for endmills of different lengths, but that will have to wait for sourcing some more hardware.

How much pressure do you have to apply to the lever for bit changes? Is it enough to possibly tweak the Z axis out of tram or is it smooth and easy?

There’s a bit of force involved, but the length of the arm affords a good bit of leverage, and the mechanism itself is wonderfully smooth (made by magical Bavarian elves as noted above), so I don’t anticipate a problem — that’s a good point though, and something I’ll have to work up a test for.