The usual DIY way to get solid PVC is to source the largest, thickest PVC pipe you can, then cut it along its length, then place it on a suitably flat surface, heat it with a heat gun, and flatten it.

That doesn’t sound like fun. I cant imagine anyone doing this and it coming out usable. Has anyone actually done this? Plus I would think the walls on PVC pipe is too thin to actually do any cutting on. Just guessing but less than a 1/4 inch. And how big a piece of usable material could you actually get even with the largest diameter PVC pipe available. Just my opinion but i’m not a big fan of this idea. No offense Will. ![]()

I agree with crookedwoodtex that the sides of the standard PVC board are a little rough when cut but not to the point of detracting from the project. I’ve made hundreds of projects from standard PVC board and no one has ever complained about the sides being rough.

If your painting the whole thing you can seal the edges pretty well. I’ve used a thin coat of auto filler after sanding, and after paint, it’s about the same as the face.

Everything I’ve seen here from @baricl or anyone else is expanded (foamed) PVC.

Here’s a pic I just took of a piece of 3/4" expanded PVC on top of solid PVC sheet.

A sign shop is using an expanded PVC called Komacel or Palight. Search your area for wholesale/trade sign suppliers. Grimco is national and may deliver locally.

For plastics, I often use https://www.tapplastics.com/.

I’m in the Bay Area and there are a few local stores.

Those pvc signs look great! What did you use for prep prior to machining and for painting pvc?

Not really any prep. Sometimes i put clear shelf paper on the piece before i cut it to reduce overspray when i spray paint the cuts. But most times i just spray the cuts, then wipe off the overspray with a rag. Then i use a 4 inch foam roller to do the top coat. Couple of top coats and dry in between top coats with a hot air gun. I just let the last top coat dry naturally because i found it gives a better finish. Then a final coat of clear spray to protect the paint. Thats it.

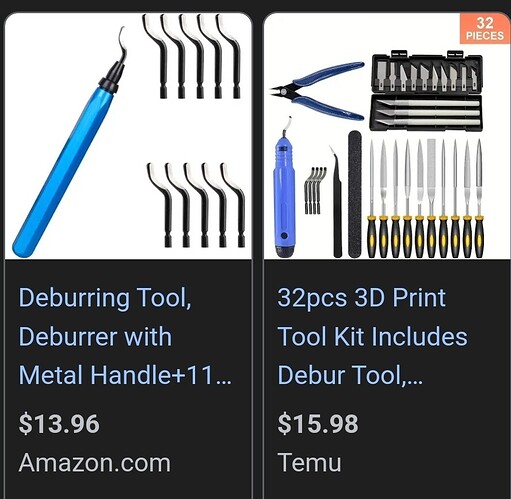

Had a friend buy a deburring tool for me and I use it on all my hdpe signs. They’re dirt cheap and are crazy fast at cleaning up most edges. I imagine they’d work on PVC also.

Apparently Corian is another material that works really well outside, and is cheaper than the average new-age plastic. Masking before carving and a suitable outdoor paint should work really well.

Wow, very cool material idea. I never thought of that. Thought it would chip, crack, or melt if routed. Im going to have to try this!

I found some more discussion on it last night. I guess Corian is a brand name for a type of acrylic, and there’s a few other brands that all do the same thing. It should cut similar to acrylic or hardwood, with nice chips if set up correctly.

Take a look at Coon Manufacturing in Tennessee.

They manufacture HDPE sheets in quite a few thicknesses and lengths.

I make all of my guitar templates (for sale) from Corian. I use 1/4” and 1/2”.

My CNC machines cut Corian easily and it never deteriorates.

I leave it stacked out doors and never worry about it. So for signs…… yeah! Why not?

But it must be laid flat as it will hold a bent shape.

checkguitars@hotmail.com for your Telecaster: Stratocaster and other templates!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.