Ok, I finally started figuring out Meshmixer and have done some decent designs. My question is what is an acceptable mesh size to allow for an accurate cut on my Nomad. It seems that the models I have been playing with in Meshmixer are huge files and the mesh is very very detailed and extremely smooth.( I imported a file into MeshCam and the estimate for machining time was like 4 hours or something crazy.(the model is 2.5 inches X 1 inch) I will be using the models I created to cut out a master to use to replicate the model on a duplicating router. Eventually I will be purchasing a Shapeoko XXL to use to cut out the bodies instead of the duplicating router.

Thanks in Advance

@Blackjack, your machining times are much more a function of your stepovers and stepdowns (along with feedrate, of course), and not as much how detailed the model is. For fine 3D work, I’ll use a finishing stepover of about 1/8 to 1/10 the cutter diameter (assuming a ball-end cutter, of course). If you don’t have a lot of concave details in your model, and use a larger ball-end for roughing, and use 3D roughing, you can remove the vast majority of the rawstock and leave just a little for finishing to refine. Then you can use a decent feedrate since the finishing cutter isn’t doing a whole lot of work. What does your typical workpiece look like?

Randy

Randy,

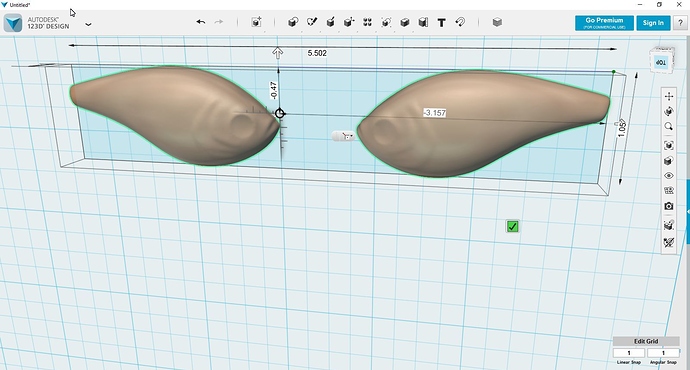

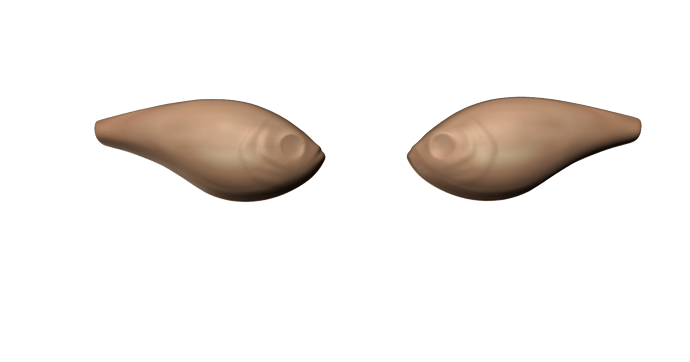

I am not sure if this what you mean but here are some screen shots from 123Design. I have not really cut anything but foam and balsa on my 883 Pro and definitely not of this level of complexity. The stock is going to be Impact-Resistant ABS 1/2" thick. These are going to be my masters as they will serve as a pattern on my carving duplicator.

Thanks for replying!