The two issues with that are maintaining the rigid stable alignment of the shapeoko rails and keeing the workpiece mounting rigid and trammed with the machine as you move it. You’d need to properly constrain the moving table in X and Y as well as the Z with the leadscrews, like a lifting knee on an old Bridgeport. That’s quite a bit of engineering to get right as you’re basically adding another axis. That said, I’d like to see it if you build it.

If you mean the vertical fixture jig, there’s quite a few nice ones out there, lots of good ideas to be had from jigs non-CNCers call “dovetail jig” where they clamp vertical and horizontal boards together to cut from the same template.

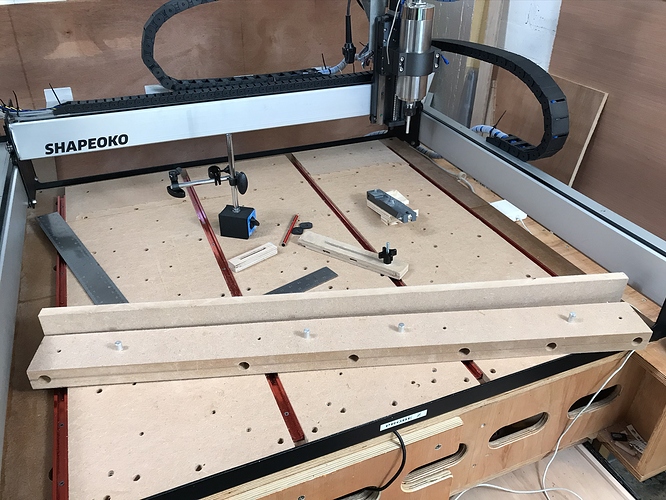

Mine was fairly simple, there’s plenty I don’t like about the V1, In the spirit of sharing my mistakes so others may learn and make different ones though;

Two layers of 18mm MDF glued together, I had the Shapeoko cut four matching 8mm holes in the bottom of the jig and the spoilboard so that it could be repeatably positioned on the front of the machine using 8mm Aluminium rod.

There are tee-bolts from my T tracks to clamp it down on the front of the spoilboard. It’s on a levelled part of the spoilboard so it’s flat in Z and consistently in the same place when I use it.

I cut the MDF to deliberately overhang the front of the machine by a few mm and then used the Shapeoko spindle to cut the front face parallel with the X rail. This is where you find out how well you’ve trammed and whether you’ve balanced your Y belt tension left to right. I planned to re-finish this periodically but I would make it differently now that I’ve used it ![]()

There’s then holes drilled front to back to allow the front clamp plate to be attached, these have long M8 bolts in but threaded rod, coach bolts, whatever you have available. The Aluminium pin is there as a consistent X stop for doing multiple parts, that was an afterthought.

I just use wingnuts on the front to clamp the front plate down, it bends a bit, should have used ply or something stiffer, but it works. There’s a vertical board attached to the bench with lots of holes in so that I can clamp & stablise longer workpieces.

What’s good;

- It fully removes from the machine

- It holds work up to the full X width vertically across the front of the machine straight with the X axis and vertical

- It was cheap to make

- It’s almost flush with the metal rail meaning I don’t lose any overhand cutting area

- Most of the parts are MDF so when I crash a toolpath into the fixture nothing bad happens

- With the HDZ travel I can easily cut 100mm+ into a vertical workpiece, with a long enough cutter (with a large enough diameter for this depth of cut)

What’s not good;

- I should have thought about repeatable X stops before construction

- I should have figured out how to provide a vertical stop to get workpieces repeatably vertical without measuring every time

- The front clamp part is too flexible

- There’s no real provision for front & rear sacrificial support boards to avoid tear-out doing things like dovetails so you end up trying to sandwich your workpiece between two bits of 4mm ply which makes getting vertical and setting zero a PITA

Does that give you some ideas about what (not) to do?