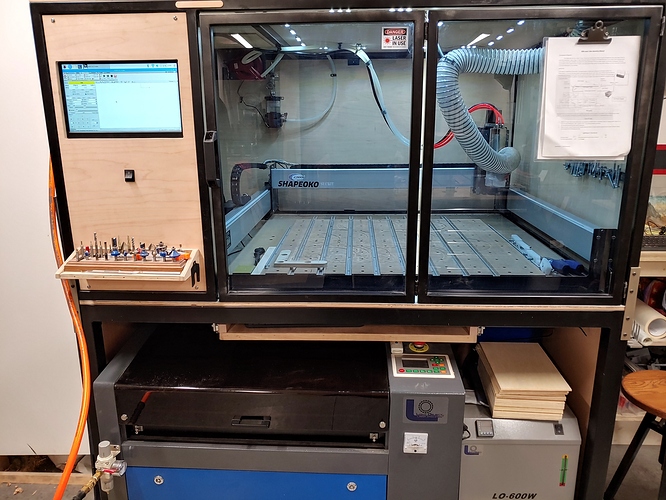

Ok, so I finally have things set up 90% after a couple years. Coming from industrial cnc work, and running a dept for many years, I miss the machines. So far I’ve been able to get things sorted. Still dealing with a possible emi issue but it’s random and seems material specific. I ordered a Sweepy 2, and the prox switches. Waiting on those.

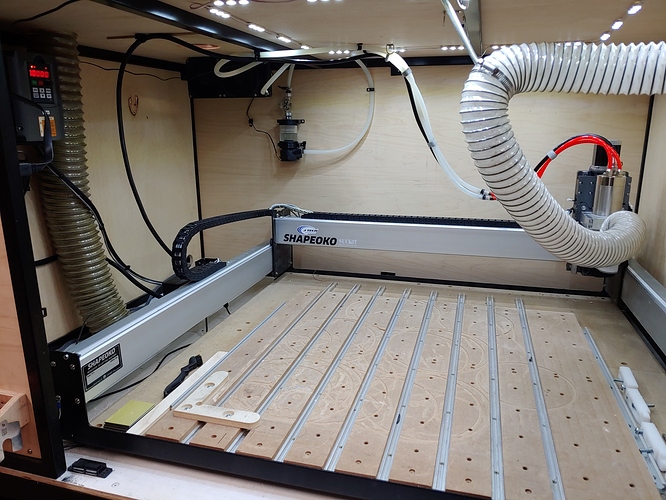

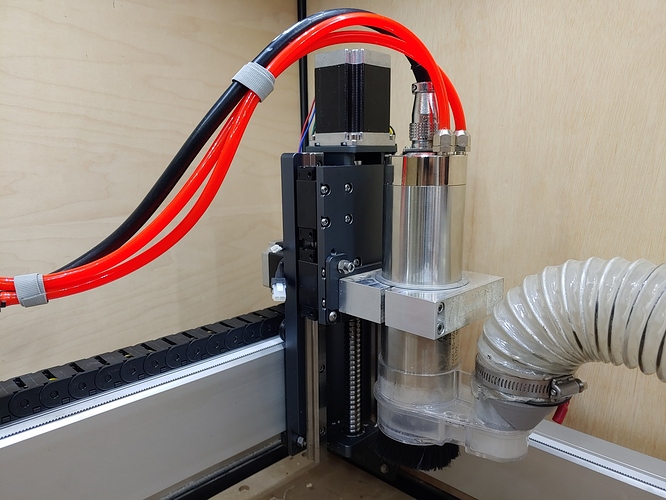

I’m considering building a shallow tray, maybe 1" deep, and adding some side walls to allow for minimal most coolant to do brass and aluminum. I hate cutting dry. Just…blah.

I’d also love to have linear rails, go figure the Pro is out now. Insert crying sad face. Looking for other ideas, upgrades, useful tips for the setup. Specifically, clamping. I can not figure out what I like. Always had a vice for the VMC machines and the bed machines had vacuum. Clamping ideas and suggestions are very welcome!

If you don’t have a bit setter yet… best upgrade imo

Are they really that handy? I’ve thought about it. I can swap a bit and zero it with a shim pretty quick…I’d have to figure out how to make one of those work with bcnc. I might switch to UGS, but I wasn’t fond of the layout.

Nice enclosure! Might want to consider adding some filter material around your electronics so they don’t collect debris, especially if metal is in your future.

I’m struggling a little with my t-slot track right now as most of the low profile clamps benefit from threaded hole placement, but you can always use the painters tape + glue method. I’ve found it’s more stable for a wider variety of materials than double sided tape. Going to be adding some vacuum pods/MDF breather as soon as they arrive, so we’ll see how that goes.

Yeah I’ll probably add a simple filter wall around that stuff. It’s actually very clean in there, and it’s all up out of the way. Eventually the whole enclosure will move and I’ll have to vent the electrical area better so filters will be perfect!

I do use the tape method a little. I do a lot of individual small items, usually batches at a time so that gets super tedious. Been sorting out corian lately, doing coasters. I make a sheet of blanks but then individually they get either engraved by the cnc or the laser.

My favorite clamps are the Gator Tooth and Tiger Claws which @Luke designed, though there are days when I wonder if I shouldn’t drill some holes for the Low Profile Vise from my Nomad, or if it wouldn’t be possible to mount a pair or even four of them for clamping larger stock in repeating setups (though the Tiger Claws and Stop work well for that when the spacing works out)

Favorite accessory is the BitSetter.

Really liked replacing the MDF filler strips with PVC (this would allow you to use coolant perhaps?) and setting them up so that they were cut off at an angle and could be installed/removed w/ a single bolt, and working up shims so that they can be shifted up (eventually I’ll have to work up projects for 1/4" thick PVC strips).

Nice looking enclosure! What lights are you using? Also, what is the system you’re using to keep the hose out of the way? A rubber band?

Thanks. I just bought some simple led pod lights off Amazon. Nothing fancy.

The hose is held up by an extension spring located in a central location to my normal work area. This way it won’t tangle at all as the machine moves. That’s why I have the hose in the front instead of the back. Coming from the back caused too many places it could wrap around the z with all the dust options being on the front.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.