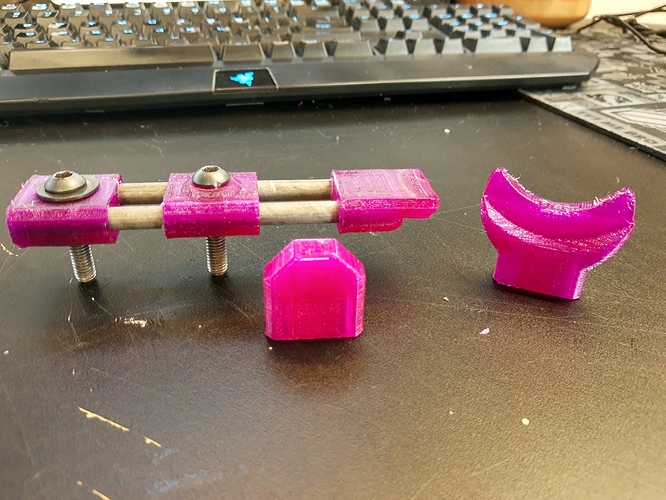

Hey gang, thought I would toss these out there. I’ve been using my own version of the oops clamps for several years now and thought I would share. I print mine out of TPU which is a flexible filament, but i print them with lots of perimeters which makes them solid yet not maring. I use 1/4 steel shafts from homedepot and 1/4 20 or M6 hardware.

The Fusion 360 project is here https://a360.co/3ftYK4s

Nice job using the tools you have available. +1

I’m not so set up, so I’ve been using Lever Clamps from PwnCNC to clamp smaller parts. I can attest to the advantage of the “Ooops” feature of plastic clamps. Been there; done that.

lol yeah. I used to have a lot of hard clamps that kept getting shorter and shorter  Those Lever Clamps look pretty good , I hadn’t seen those before.

Those Lever Clamps look pretty good , I hadn’t seen those before.

I’m new here and waiting on my Shapoko Pro to arrive.

Posts like yours have inspired me to make my own also.

I made these Tiger Claw replica low profile clamps today on my 3D printer. I cant justify $70 for the SS ones when I can make these for $1.50 each. Sure it takes 4 hours to print a complete set of 4 with stops, but I saved a bunch of $$. The other upside is they won’t damage the cutter if accidentally hit during operation, and if they get ruined, i can just print a new replacement.

very clever. It’s great that this type of manufacturing ability is something we can do at home!

This topic was automatically closed after 30 days. New replies are no longer allowed.