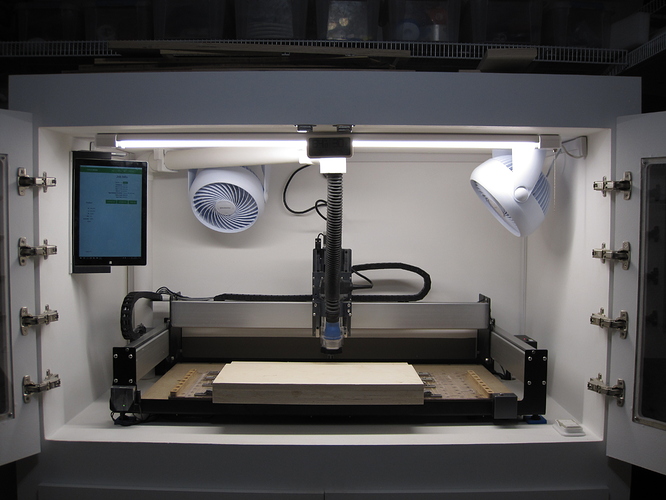

Here is my enclosure to add to the “Enclosure Zoo”.

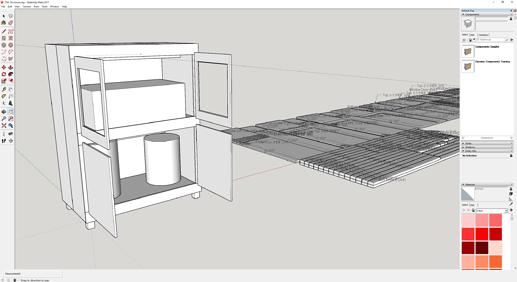

I started in early June 2020 with a stack of MDF and 2x4 lumber. I was rather nervous about this build, I’m over 50 and this is the first time I have ever owned/used a circular saw. I felt I had a good design and plan, but knew I had very little experience so this was all going to be about my execution.

I worked on it a little each weekday night, and most of day on weekends. It was a really good COVID lockdown distraction. Roughly a month later I was not “done”, but I was far enough along that I had a solid and stable place to start constructing my Shapeoko XL.

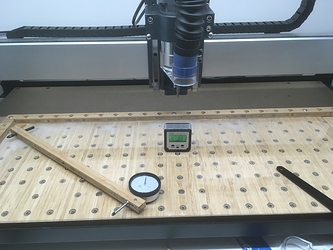

After another month of nights/weekends, the Shapeoko was functional. It’s first series of jobs was to create the tools and parts needed to tune the machine, wasteboard, etc. Eventually leading to its first real-world task which was to mill the upper doors and lexan windows.

Four months have passed since I started, and this past weekend I got to the point where I am “almost done”. I want to make a plug for the opening I left in the back of the enclosure that is intended for when I need to extend the Y axis (aka “tiling”). I’m thinking foam, but still thinking about how I want it to look and work. I’ve really enjoyed this build, it’s been a great COVID distraction.

So I present to you, the (close enough to call it) finished enclosure. It’s not the best Shapeoko enclosure, but it’s mine and I am really proud of how it turned out.