Edit: This may be the same problem as listed here

Edit x2: It is not the same problem as listed above, the zero holds, and is correct until I run it and it does… whatever it is doing.

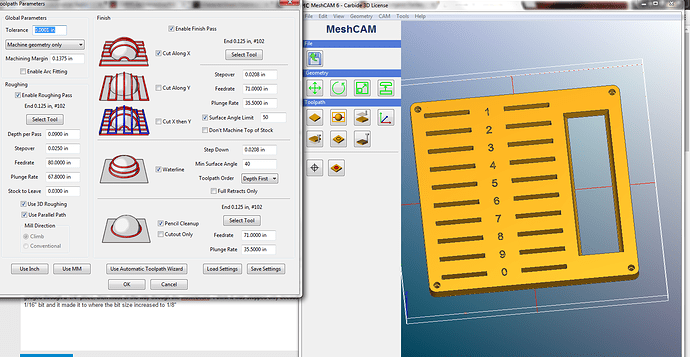

Ok, So this is the second time this has happened in a row, different files completely. (Two different days as well, though that should change nothing) Ill run the file through meshcam v6. The first time using the carbide autopath, and the second time using the regular toolpath generator with data from gwizard.

I’ll run the meshcam into carbide create, zero to the corner, but when I run it the first thing the nomad does is goes to the correct X Y, but then gouges into the piece as far as it can press in, and then tries to move in the XY. The first time it gouged through a 1/4" piece, then most of the way through the wasteboard. I think it was stopped only because it was a 1/16" bit and it made it to where the bit size increased to 1/8." Fortunately the bit broke, so only the piece was ruined.

I should be on the newest version of both meshcam, and carbide create.

This isn’t the first piece I’ve done, and I’ve never had this problem before the last two times. Any ideas?

[/quote]

Ok, So this is the second time this has happened in a row, different files completely. (Two different days as well, though that should change nothing) Ill run the file through meshcam v6. The first time using the carbide autopath, and the second time using the regular toolpath generator with data from gwizard.

I’ll run the meshcam into carbide create, zero to the corner, but when I run it the first thing the nomad does is goes to the correct X Y, but then gouges into the piece as far as it can press in, and then tries to move in the XY. The first time it gouged through a 1/4" piece, then most of the way through the wasteboard. I think it was stopped only because it was a 1/16" bit and it made it to where the bit size increased to 1/8." Fortunately the bit broke, so only the piece was ruined.

I should be on the newest version of both meshcam, and carbide create.

This isn’t the first piece I’ve done, and I’ve never had this problem before the last two times. Any ideas?