Ok, as promised, here’s the how to. Could probably use a little editing, but it hits all the high spots.

-----How to upgrade the spindle motor for the Carbide3D Nomad 883 Pro to 70 Watts -----

Keep in mind that you are modifying a potentially dangerous

piece of equipment with spinning sharp things. Your mother would be very

upset if you hurt yourself. Stay safe.

This most certainly will void your warranty.

If you are expecting a night and day difference doing this upgrade you

will be disappointed. It makes a difference, it does not make a huge

difference.

You lose some Z travel doing this modification using the standard

Nomad 883 Pro enclosure. If you are using a different enclosure you may not

need to reduce the Z travel. The work envelope doesn’t necessarily change,

but may mean you need to use shorter tools for work near the limit.

This is how I did this process on my 883 Pro. Carbide3D is always making

updates and improvements in their products, and the material here may not be

accurate for newer or older machines.

Tools required

2.5mm hex wrench/driver, at least 3 inches long. T-Handles are not recommended.

1.5mm hex driver

A large flat bladed screwdriver

Hobby knife. Not a utility knife.

A soldering iron

Materials Required

1 Wantai Brushless Motor, model 42BLF03. (Find on ebay for about $30 plus shipping)

This motor is rated for 70 watts vs the 50 of the original. The 42BL motors

match the stock motor mounting holes. This motor is however 16mm longer (79mm)

than the stock motor. The driver IC should be able to handle this with no

issues, and there is plenty of power available from the PSU.

16mm ~ 0.63 inches

You should consider the higher powered motor as a consumable item as it most

certainly does not have the higher quality bearings that Carbide3D specifies

for the original motor.

Solder

Loctite - Medium.

M+F connector of choice. I used a solder cup style DB-9 without backshell. It

isn’t strictly necessary to use a connector, but I did.

A piece of ~1/8" thick brass or aluminum material to make a new limit stop. Use

what you have at hand, but it should be at least as thick as the existing stop.

----------------------------- How to ----------------------------------------

Remove the power plug from the wall and disconnect the USB cable. Both. Really.

The controller board will stay powered if the USB cable is plugged into

a PC, even if the main power is turned off. You can damage the pins on the

controller or the wiring if your soldering iron is grounded (which is

the normal way they are built) and the controller is powered on.

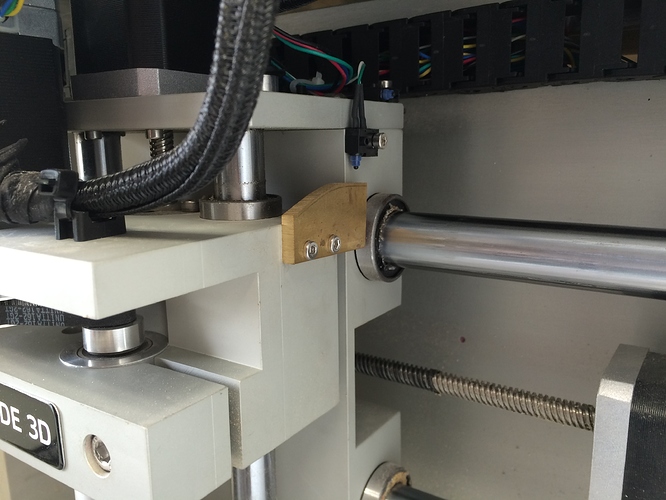

If you are using the standard Nomad Pro enclosure or a replacement without

additional height above the carriage you need to make a new limit stop:

Remove the limit stop from the right side of the Z-carriage with the 2.5mm hex

driver. Use this as a pattern to make a new one that is at least 17mm taller.

Install your new stop. Push the Z axis all the way to the top, and be sure the

new stop engages the limit switch. Do not carelessly slam the Z carriage up into

the switch while fitting and sizing or you will break the switch internally.

Hold the new motor next to the old one and be sure it clears the top of the

enclosure. If it does not note the additional space you need and make a

new stop. This is a pretty easy part to make so just do it by hand.

If you can’t make this part by hand…you probably shouldn’t be

trying this process. You could also just drill and tap new holes for the

existing stop, but it’s very inconvenient to do so accurately without a lot

of disassembly. Seriously: Do not carelessly slam the Z carriage up into the

switch while fitting and sizing or you will break the switch and it is not

obviously broken.

Use the 2.5mm hex driver to loosen the 4 cap screws that hold the motor to

the carriage. The back two can be easily accessed through two holes

in the underside of the Z carriage. The motor should be easy to move a few mm

closer to the spindle which makes the belt easy to remove.

Remove the belt from the pulleys and carriage.

Use the 1.5mm hex driver to back off the set screw from the large pulley. It’s

way down in there and may not be visible. You don’t need to remove the set

screw, you just need to back it off 5 or 6 turns. If you remove it you will

drop it. Its easy to lose and really tiny.

Use the large flat bladed screwdriver to lever off the big pulley from the motor.

If you’re smart you’ll put a (metal) putty knife between the shaft of the

screwdriver and the underside of the motor mount on the carriage so you

don’t leave a mark like I did. This should take a little effort but if it’s

LOTS of effort check the set screw again, think about what you are doing,

and don’t break or bend anything.

Remove the 4 cap screws you loosened earlier that hold the motor to the

mount with the 2.5mm driver.

VERY CAREFULLY and SLOWLY, with multiple shallow cuts, cut through the heat

shrink at the end of the cable cover braid lengthwise. Do not use a utility

knife for this task. The shrink tube is adhered to the braid. Be VERY careful

not to cut the wires or insulation. Peel the heat shrink off the end of the

chafe braid.

Peel back the chafe braid. It will just unwind from around the wire bundle.

You can now cut the wires about 1.5" or so from the motor. This leaves enough

to put a connector onto the old motor so you can put it back in if you need to.

Prepare the new motor. My motor did not have a flat on the shaft to accommodate

the set screw, so I added one with a file. The shaft material is pretty soft.

The original motor has a flat. If you make the flat too deep the set screw

will be overdriven and get jammed between the inside of the pulley and the shaft

which is “a problem.” You don’t need a deep flat, just enough for the set screw

to catch. The flat on the original motor shaft is much deeper than necessary.

Wire the motor, matching the wires. Be sure to match the group of 5 wires to

the group of 5 wires and the group of 3 to the group of 3. The group of

5 is the hall sensor assembly, and has colors that are the same as those in the

phases. These wires are not interchangeable. If you want to use a connector,

do that. A simple 9 pin DB-9 works fine, but many different connectors will

work. The wire is 26 gauge, so be sure the connector/pin you

choose can support wire this small. I -strongly- recommend you do not use

automotive type butt connectors. If you use a DB-9, pot the back of the

connector with hot glue to help with vibration/fatigue. If you need to do so,

hot glue is easier to remove than silicone. There really isn’t room for a

normal DB-9 backshell.

Be careful that you leave enough slack so that the cable doesn’t bind or pull

hard against the geometry of the carriage anywhere. Any solder connections

should be between the cable-tie clip and the motor. Do not solder anywhere that

will flex later.

Install the motor and tension the belt

- Place the motor into the carriage without any screws.

- Put the pulley back on, aligning the set screw with the flat in the shaft.

- Align the pulley vertically with the small pulley on the spindle

- Loosely install the motor with the cap screws. This is a little fussy.

Don’t apply loctite at this time. - Put the belt back on, and use it as a reference to adjust any pulley

misalignment. - Reinstall the set screw on the big pulley. It should be firmly tightened,

but not “Gorilla Tight” - Push gently on the motor away from the spindle cartridge to apply tension

to the belt. Tighten the motor mount screws. Light belt tension is

sufficient. - Remove one motor mount screw at a time, apply Loctite to each screw and

replace them. - Check your wiring carefully one more time. Check for “whiskers” between the

connections, shorts, melted wire insulation, etc.

Plug it in, fire it up, start the spindle. If it makes noise, the tension is

too high on the belt, so back off the screws and try again. If the motor

doesn’t rotate, check the wiring, check that the wires are firmly connected.

Run the spindle at high and low speeds (S10000 M3 - start spindle at 10k rpm,

M5 stop spindle)

I recommend wrapping the connector area with silicone tape (“Rescue

Tape”) to seal it from swarf and other material that might be kicked up.

Electrical tape is not a good substitute in this case. Then cover as much as

you can with the chafe shield you unwrapped at the beginning of the process.

If you cut off the zip-tie earlier reinstall a new one now. Do not operate

without that zip-tie in place, or the wires will fatigue and break off at

the connectors or internally at the motor over time. Be sure to leave enough

slack so that Z travel doesn’t pull the cables hard against an edge.

This is how I did this modification. It might or might not work for you

and you might have better ways to accomplish the same end. This worked for

me and I’m happy with the result.