Yeah. I’m still testing, but I haven’t noticed any performance gains. My hope is that there will be enough extra torque to power through some of the cuts that were previously stalling the spindle. I’m gonna try some mild steel this week with a Fusion360 file that was giving me problems. This will really point out the (hopefully big) differences. I’m also looking into the possibility of somehow fitting either a Nema 23 motor or maybe using two motors connected to a common pulley. I know this has been done in other applications, just not sure how.

Jerry

Was just thinking myself about how I would get two running in parallel…I think there’s room with a bracket on the carriage and a new/different pulley on the spindle…

I don’t think I’ll go further than just thinking about it though. If I really feel the need for more power, at this point I would just add a shapeoko3 to the stable.

Just out of curiosity, do you have the new version spindle motor driver (the one with 6 chips) and brass pulley?

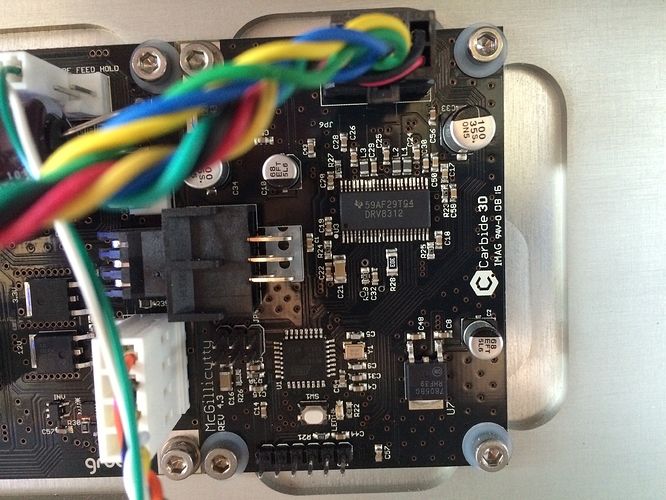

Well I’ll be… Carbide 3D uses Imagineering for PCB’s! Me too.