The default feed speed max is 5000mm/min or 196.85ipm.

“Chipload = Feedrate / (nb_flutes x RPM)”, it doesn’t “scale linearly with endmill diameter”.

My admittedly limited experience suggests that material unit power increases with the square root of Janka hardness (not “linearly”).

Unit power is dependent on material characteristics and endmill condition. IMO its a lot easier and much more accurate to measure cutting power consumption than try to predict it.

Cutting power, in conjunction with speed and endmill diameter can tell you cutting force.

“how long [did] this magical runout adjustement hold”?

I stand corrected, thanks! This is one of those things that for some reason I had come to believe without checking, probably due to the fact that all recommended feeds in the Shapeoko chart max out at 100"/min.

I’ll edit the post to avoid future misinformation

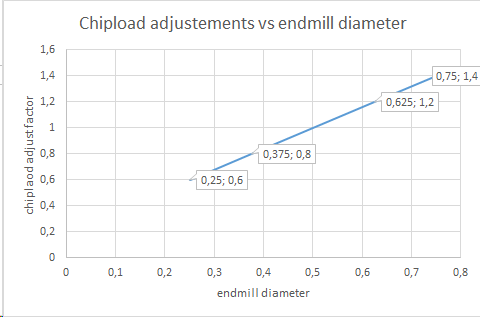

I was not being clear, my assumption was that the max chipload that a given endmill can take, regardless of material being cut, is proportional to the endmill diameter (i.e. that a 1/4" endmill can probably reach a MAX chipload of twice what the corresponding 1/8" endmill can). I’ll have to check manufacturer datasheets to see if this is correct or not.

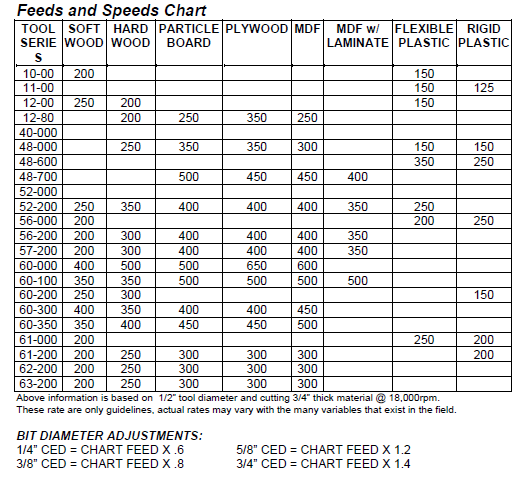

[EDIT: I opened a random (Onsruds’) manufacturer’s recommandation for feeds and speeds, found this table and its interesting foot note :

If I plot the feeds & speeds adjustment factor as a function of the endmill diameter I get this:

If I knew how to do this I would certainly try it, but what you described earlier in the thread went over my head, I’ll have to give it a second read…

I’ve not yet had the opportunity to do a realistic job (more than short tests cuts) after tapping my endmill into the low runout values. I’ll report when I do.

Does the power of these spindles every come into play before the oomph/rigidity of the stock Shapeoko unit is challenged?

These routers have plenty of power to keep up with mods without issue. Ridgidity is the weak link from the beginning if your main concern is cutting metal.

In my experience and research, if you reach a 0.005 chipload and want more MRR, its better to increase load with axial doc.

Did I mention I picked up a 60krpm spindle, should be here next week. Btw love the data, is there any way we can see your test rig? I was thinking a vice on rails with strain gauges.

But that refers to power consumption without consideration of rigidity?

(don’t mind me, just following up on my latest tests)

With the newfound revelation that I can go 200"/min (facepalm…), and since I wanted to test chiploads for soft plastics, in my case HDPE, I extended the table by another factor of x2 (consistent with my previous finding in HDPE, and data from Winston’s video on machining HDPE on the Nomad)

| HDPE | Acrylic | Soft wood / MDF | Hard wood | Aluminium | ||

|---|---|---|---|---|---|---|

| acrylic+100% | softwood + 20% | hardwood + 100% | baseline + 100% | baseline | ||

| 1/16" | 0.0024"/0.06mm | 0.0012"/0.03mm | 0.001"/0.025mm | 0.0005"/0.0125mm | 0.00025"/0.0063mm | half of 1/8" values |

| 1/8" | 0.005"/0.12mm | 0.0024"/0.06mm | 0.002"/0.05mm | 0.001"/0.025mm | 0.0005"/0.0127mm | half of 1/4" values |

| 1/4" | 0.01"/0.254mm | 0.0048"/0.12 mm | 0.004"/0.1mm | 0.002"/0.05mm | 0.001"/0.0254mm | baseline |

and got those gorgeous HDPE chips using a 2-flute 1/4" endmill at 5000mm/min and 10.000RPM, i.e. a fat chipload of 0.01"

Sure, it makes more sense to use an O-flute at half the feedrate, but watching the machine hog HDPE was fun.

[EDIT] I fixed the typos, I obviously meant 0.01", not 0.1". I’m so bad at this Imperial units things, I wish I could use millimeters only and still be understood out here

Thanks so much for rationalizing/quantifying this whole subject for us non-engineers.

Machine rigidity (torsional stiffness) determines how much machine deflection (positional error) results from a given cutting force, which is plotted in the charts. If cutting force exceeds the capability of the machine, something will slip/break. Here’s one way of measuring that limit. Fortunately(?), luggage scales will suffice for Shapeokos because they are far more limited in force. Applying forces to the ends of endmills and measuring the resulting endmill deflections would help determine acceptable forces in the X, Y, and Z axes.

Looks like this 60kRPM spindle did you get the collets too?

I’ve learned that it’s much easier and accurate to measure spindle cutting power, RPM, and calculate cutting force than it is to measure/calculate it. But, I’d be happy to provide info on both approaches if you like.

What depth and width of cut?

DOC was 0.125", stepover was probably the same I would have to double check

The end of Podcast 006 supports the @Vince.Fab claim that 0.001" is a good starting point for chip-load, even in much harder metals. This video explains the value of using greater cut depths (which the lower chip loads enable) and demonstrates the value of using quiet spindles. Or, you could “drink the Kool-Aid” provided in Podcast 007.

The Nomad liked 0.002 chipload in titanium…

So it seems like a Podcast w/o any video? Is there a link to a video you intended to post?

I listened to about the last 1/4th of program #6, so I can learn about the chipload vs. DOC thing, but I didn’t hear it, can you narrow-down where they go through that please/

TIA!

Using what endmill diameter ?

Just asking because I recently applied the recipe from the table discussed above in the thread, to do a profile cut using a 1/8" endmill in aluminium, targeting a chipload of 0.0005" (halving the 0.001" for 1/4"), and it turned out to be too little, so I used +50% feedrate override and the cut went perfectly. So I would tend to update that table with 0.00075" starting value for 1/8" and 0.0015" for 1/4".

Blockquote

So it seems like a Podcast w/o any video? Is there a link to a video you intended to post?

I listened to about the last 1/4th of program #6, so I can learn about the chipload vs. DOC thing, but I didn’t hear it, can you narrow-down where they go through that please/

TIA!

No video that I know of as mentioned in the Podcast 001.

OOPS forgot the link to the DOC and sound of cut video - sorry! I’ll add it to the original post.

Starting chip-load mention is about 57 minutes into Podcast 006.

Thanks for making me look up TIA! I’m kind of old I guess.