@gmack:

Well, seeing is believing, I have to admit you opened my eyes.

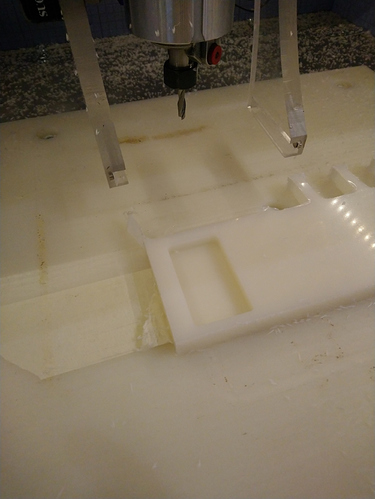

- First test: 1/4" 2 flute endmill; pocketing in HDPE, 25.000RPM, 100ipm, DOC 0.1"

(excuse the lousy video quality, I captured this through the acrylic front window of my enclosure)

Perfect cut,

And nice clean chips

And the cutter was not even warm at the end.

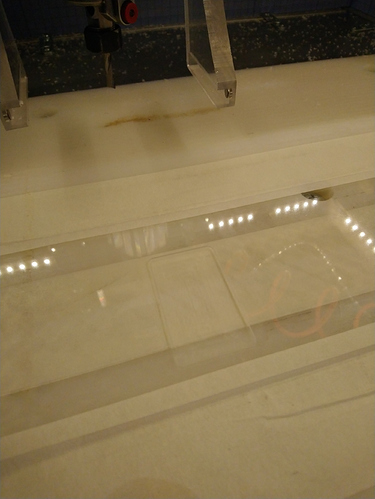

- Second test: 1/4" 2 flute endmill; pocketing in Acrylic, 25.000RPM, 100ipm, DOC 0.04" (just because my acrylic stock was only 0.08" thick):

Again very clean cut:

and still getting good chips:

And…I confirm that there is no way I can bear the sound 25.000 RPM for a long time, nor can my neighbors at 10pm.

So, it looks to me like there will be two conclusions:

- if you can/are willing to max out RPM first, this is the best way (given the optimization of cutting forces) and you can use low chiploads

- if you can’t or won’t, then you should increase the chipload (and accept higher cutting forces) as an alternative way to keep things cool. Call it the hobbyist/amateur way, it still works

Now I can’t wait to receive my water-cooled spindle, to further venture in high RPM territory.