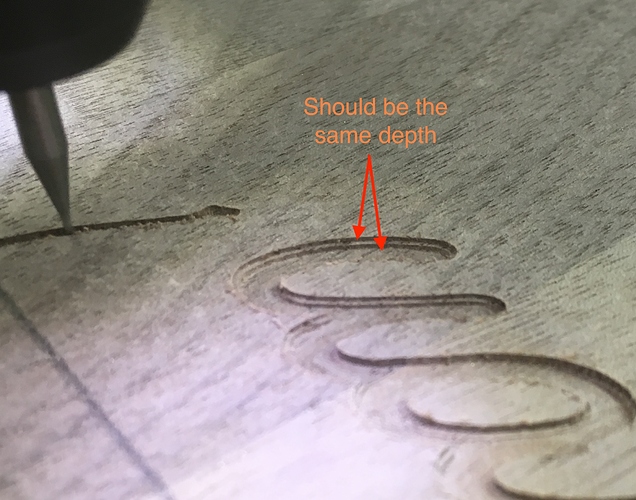

I seem to have issues on my z axis when doing shallow engravings. The machine will be cutting at the right depth then it will start going too shallow, then go deeper again seemingly arbitrarily. This is on a 0.8mm deep pass, so the differences play in the 1/10s of mm.

This is an example of what I mean:

Furthermore I’m starting to wonder if the problem exists on the x and y axis as well. I started a cut today which was too shallow, so I stopped the machine, rezeroed using my saved coordinates and brought down my z-axis an extra 0.2mm … yet the cutter was off of my zero mark by at least 2mm on the y axis. (for this one, I’m leaving open the possibility that I mistakenly nudge it when trying to adjust the z, but it seems unlikely)

I thought maybe the problem was the hardware, I went through all the steps to verify tension on belts and wheels and such, everything seems good to go, yet the issue persists.

So, at this point I’m wondering if I’m expecting too much from this machine, are slight inconsistencies to be expected on a small machine like the shapeoko? Otherwise, if this suggestion underestimates what the shapeoko can do, what might be the problem?