It’s a fair point, I mean the belts are good, and if you want MM precision I have no worries there, my wood projects are on point. The parts I’m making are accurate to 0.1mm but my repeatability is far from that when re-starting a job.

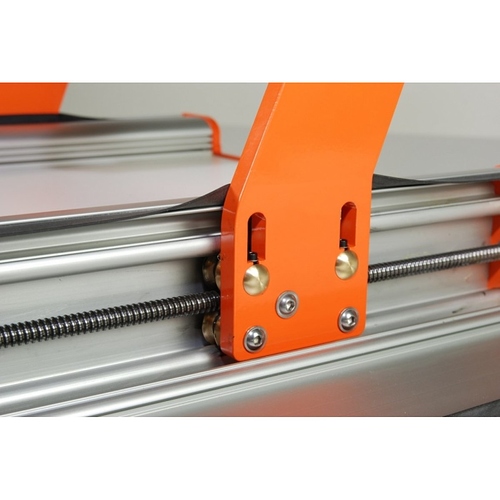

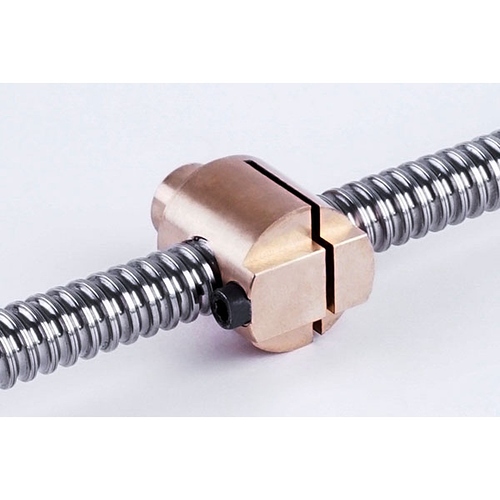

If you were to improve the V wheels/guides then I think you’d be better off doing both guides and drive at the same time. I know Openbuilds do a ball screw and v wheel combination all in one unit which looks interesting. If I were to do it I do think you’d be better off doing both, I thought the gearing would be a good half way house but @WillAdams makes some great points.

I too thought about the twist, but you’d need whole new wrap around section and it could get messy, I think replacing the X for a custom setup would be easier with guide rails and ball drive.

The thing for me is a nomad is incredibly accurate, repeatable and gives a great finish (on metal), something I think could be improved on the S3. I have had fantastic results and the S3 has exceeded my expectation, but I’d love to see what a ball drive setup with linear guides would do. I Nomad on steroids so to speak.

I love my new Z - it’s so much more repeatable and dangerous than the belt setup - there is no more jamming or sticking which was causing me many problems.

I also have no desire any more for a bigger machine, I looking at 99% of my projects they will always be less than 50x50cm, and 90% smaller than 10 x 10cm.

What I’m keen to do is have a really solid structure I can build from and upgrade as feel I need to. This is why I’m considering giving the shapeoko brains and guts to the bare bones 6040 machine, it has the size I need but a more rigid structure and it way cheaper than building my own machine from scratch.

Ages ago, Carbide 3d sent out a survey to ask what they should work on, do we know if they looked at pumping out a new machine? I feel it’s time for a Shapeoko 4 - a DIY kit we can build, upgrade and work with but driven by ball screw and guides and maybe a slightly bigger work area?