Shapeoko 3 with touch probe:

Would be great to be able to probe not just the lower left corner but also the 3 other one!

Would be great when doing two side work.

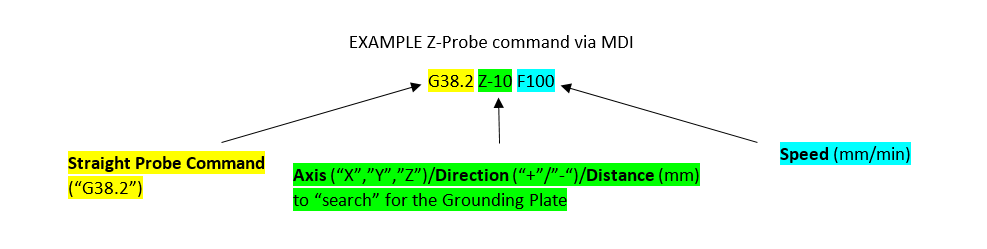

Using Motion, you could enter probe commands in the MDI.

Using something else, you could write a macro.

Most of my 2 sided machining has utilized the same zero coords. I can see where probing a corner in a different location would be useful, though might add some confusion to some users. There is a wide variety of skill sets and carbide motion/create tend to aim at the newer user.

So a basic/advanced tab would be great!

Can you provide command example for probing X and Y on the upper left corner with a 1/4" bit?

G38.2 X-20 F100 and G38.2 Y20 F100 ? What about the size of the bit?

Hey Neil,

I’ve seen you mention this before, and I was equal parts too embarrassed to ask and too lazy/preoccupied to search. Let me know if I’m understanding this correctly…

From my understanding, you could enter multiple MDI commands at once. If entering multiple commands in the MDI at once, the user would have to enter Straight Probe Command for Z, G92 Z(known touch plate height), Z Move (safe distance off of touch plate), X Move (conservative X distance from Z probe location), Z Move (set distance below surface of the touch plate), Straight Probe Command for X, G92 X(known location of touch plate side to X origin of touch plate), X Move (safe distance away from touch plate), Y Move (set distance away to clear touch plate in X direction), X Move (set distance to position for Y probing), Straight Probe Command for Y, G92 Y(known location of touch plate side to Y origin of touch plate), and lastly, jog to X,Y origin with a safe Z height.

Wowzers! Does that sound right?

Hey Vincent,

If I understand correctly you would calculate the radius of the tool then add that to the known distance from the side of the touch plate to the origin. I don’t have a BitZero in front of me at the moment but let’s say the distance from the side to 0,0 is 10mm then I’m assuming that you would then enter the X probing command sequence for a 1/4" gage pin: G38.2 X-20 F100 G92 X13.175.

10mm + ((.250in/2)*25.4mm/1in) = 13.175mm

Could someone confirm this?

*edited because I originally subtracted the radius of the tool from the 10mm.

I imagine it should be something like that. I found this old post very interesting also : Show me your probing macros

But I would really like to have an exemple of the complete workflow, that’s my way to understand. As soon as I have the complete macro, I’ll be able to understand better and mod it to other need.

Are you using a gcode sender other than CM?

I suppose you could always test your hypothesis with conservative speeds and keep your hand over an E-stop on the ready.

No, just Cm for now, but looking for a “more complete” one actually…

Jog to left side of probe, below the surface of probe.

G91 (incremental mode)

G21 (metric)

G38.2 X25 F75 (Probe X to the right 25mm at a feedrate of 75mm/min)

G0 X-2 (retract X 2mm)

G38.2 X25 F45 (Probe X to the right 25mm at a feedrate of 45mm/min)

G10 L20 P1 X-10.175 (set current location as 7mm probe thickness + endmill radius left of X0)

Jog to back of probe, below the surface of probe.

G38.2 Y-25 F75 (Probe Y to the front 25mm at a feedrate of 75mm/min)

G0 Y2 (retract Y 2mm back)

G38.2 Y-25 F45 (Probe Y to the front 25mm at a feedrate of 45mm/min)

G10 L20 P1 Y10.175 (set current location as 7mm probe thickness + endmill radius back from Y0)

G90 (IMPORTANT! Restore absolute motion mode)

Restore G20 if you use inches.

I don’t know if you can do that in Motion.

If you’re running a probe as a macro or a file, you would want to add dwell commands around the G10L20 EEPROM writes.

I try to avoid G92 unless I have a good reason for it.

Here’s my CNCjs macro for the C3D probe.

Those need to be separate commands, on separate lines.

G38.2 X-20 F100

G92 X13.175

Thanks a lot! I’ll take time to test all that!

And also CNCjs seems to be great!

Off topic, but did you fill the Machine profile in CNCjs?

This topic was automatically closed after 30 days. New replies are no longer allowed.