The dowel pin method is shown in How to make a part that is too large for the machine

The other method is shown in the following pictures:

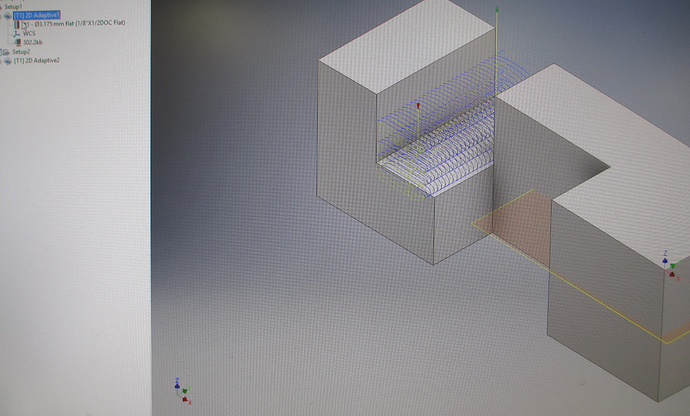

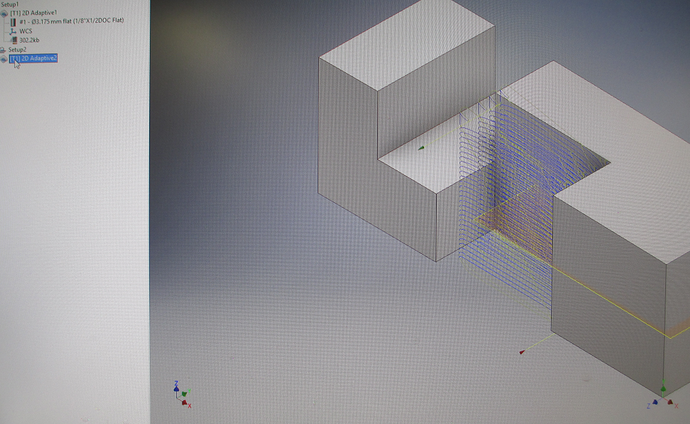

First, the CAD model (sorry for the camera screen shots-- I don’t have good screen grab software on the shop machine) with toolpaths (InventorHSM-- Fusion360 will do the same)

Note the gnomon for the origins is not in the same place or orientation for the two paths.(for this demo, I whaled it out in soft wood, 2000mm/min, 10KRPM, using presized stock for speed, so there is no surfacing and I set Z origin at the top. The original parts were run in aluminum, and the Z=0 was at the bed surface)

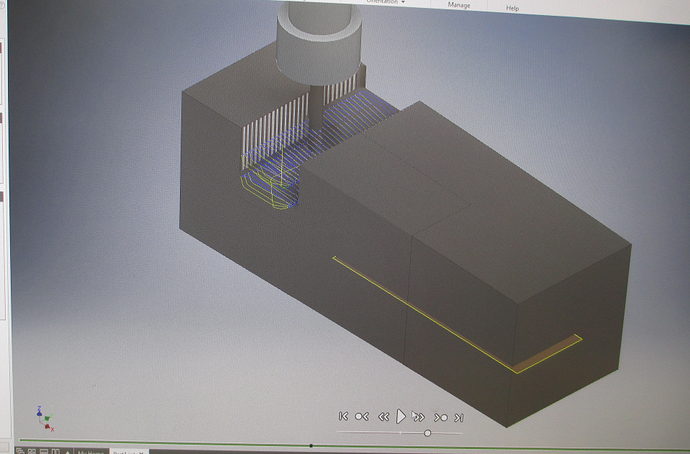

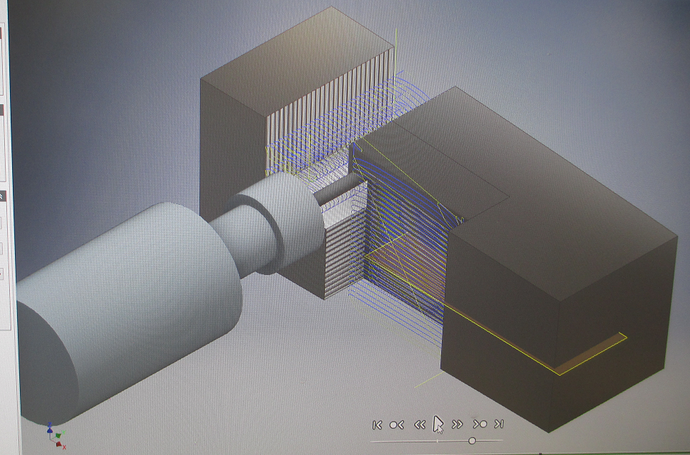

The simulation shows the operations to follow:

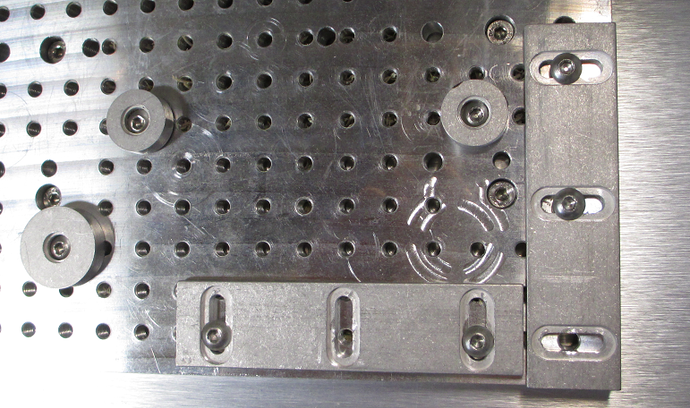

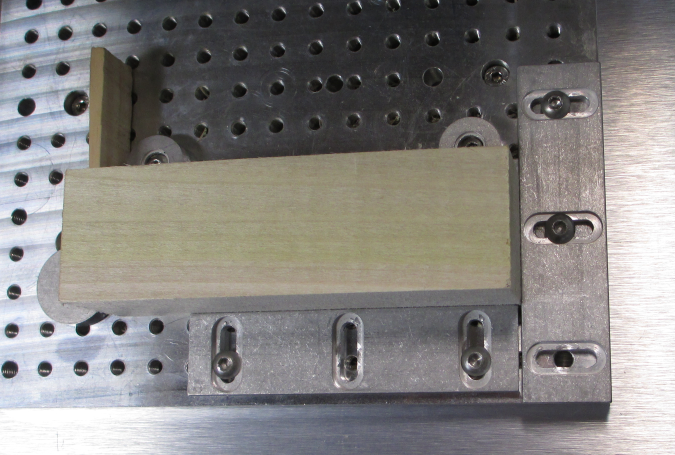

Now, the setup…

The rail parallel to X was set up using a test indicator in the spindle and is parallel to the x axis within 0.01mm over 100mm. This is the Y reference, and Y=0 is the positive Y edge. The rail at the right (replaced the pin for wood…) is the X reference, and is set so the positive Y end is maybe 0.02 or 0.03mm farther to the right, so there is a positive point for the stock to seat. The holding is with cams. The rightmost locks counterclockwise to draw the material to the right, the leftmost locks clockwise to pull the material down (with the wedge to make up and spread load on the wood end grain), and the middle one locks whichever way once the other two are locked in. The idea is to have the locks draw the material to the reference faces.

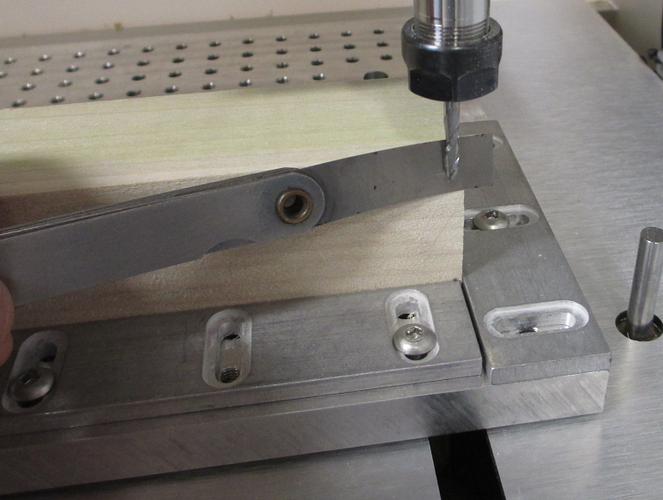

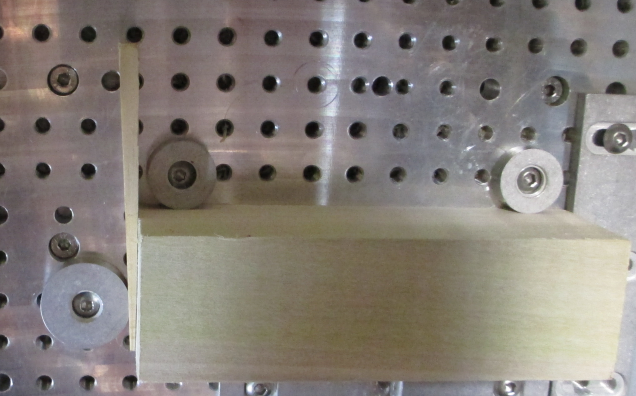

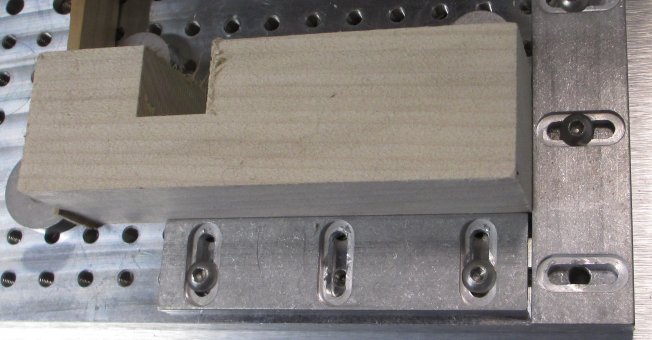

The material locked in for the first position:

Checking the zero for the Y axis. The adjustment to the position for zero is 0.10mm feeler plus half the cutter diamerter: 1.68mm.

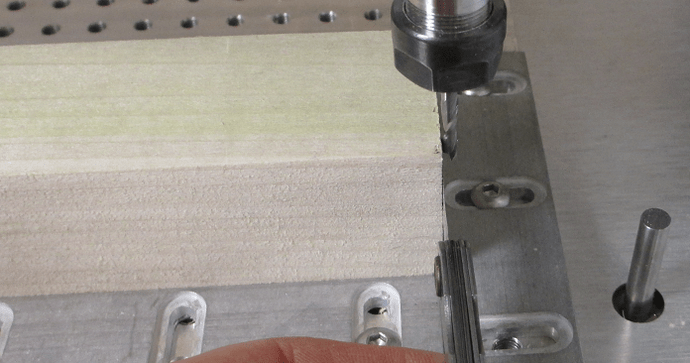

and the X:

and the cutter over zero using the fast position to zero:

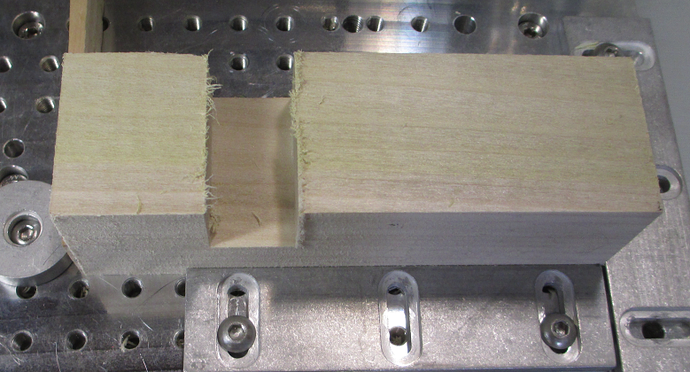

The first position cut:

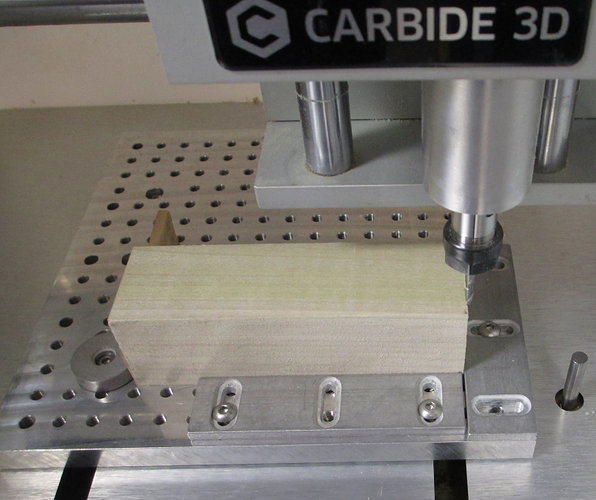

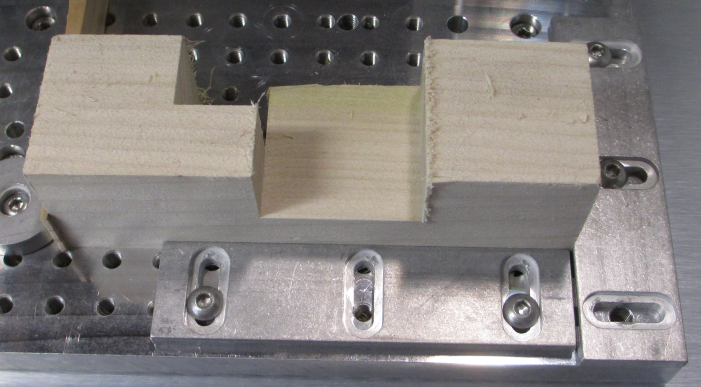

Reset in the second:

The edges of the face that wend down were given a light touch with a sharp file to remove any splintering so the part sit flat. Similar with aluminum or any other material: deburr the edges or the part will NOT sit flat

and done:

Workholding is the key in all machining, and doubly so in CNC. I hope this gives you some ideas.