Shapeoko 3XXL has run flawlessly up to a few weeks ago.

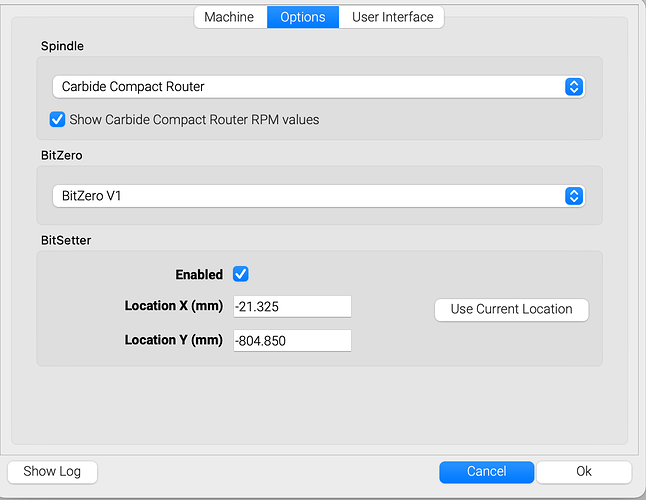

Installed JTech Pro 7W laser.

Using Lightburn to run the laser.

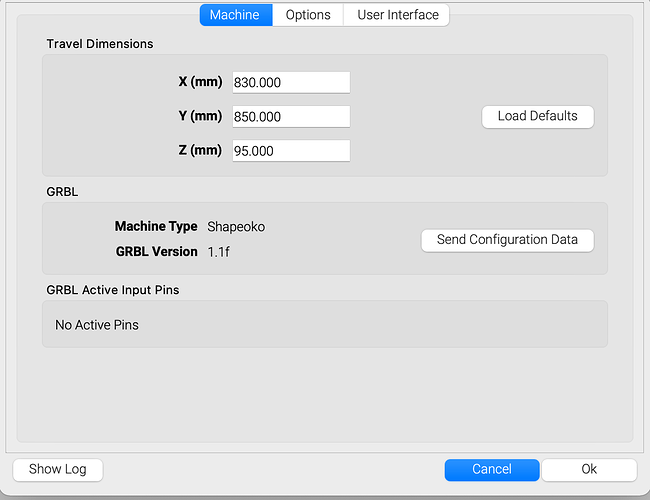

CC 743 CM 575

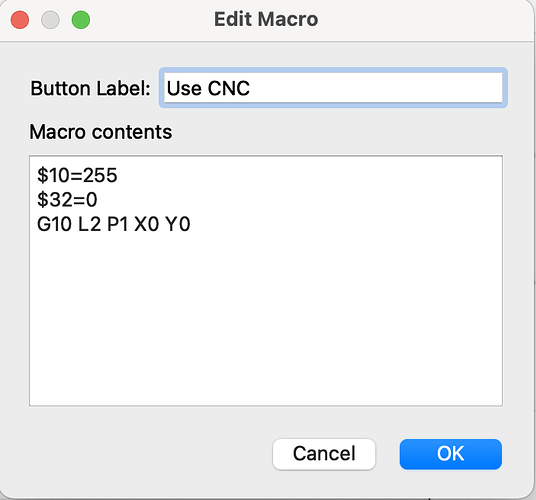

The first time switching back Shapeoko was all over, would not jog properly, Z axis wouldn’t move at all. After searching the forums I found a few threads on creating a macro in lightburn “Use CNC” with the following parameters $10=255

$32=0

G10 L2 P1 X0 Y0

I set up my work piece, X & Y are correct without resetting. Set my Z zero using the eyeball method. Load file, install 1/4" 201 and machine runs over to bitsetter as usual.

Project is set, first cut is 2 oval slots 25.5mm deep on a 25mm board.

Everything seems OK until about the 26mm mark where it just keeps going. I stopped it at 38mm (that is 12mm into the spoilboard).

This has happened the last 3 projects. Any idea what is going on?