I get a preview too if I do that but the contour toolpath does not show and the texture toolpath etched beyond the border of the character.

What diameter do you have set for the tool?

3.175mm, which does not seem right.

Please try a smaller diameter which matches what the diamond drag engraver will actually cut.

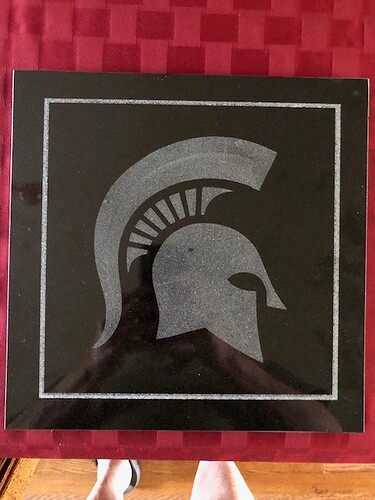

Just tried my first project with the MC Etcher. Results were acceptable but the cut was not very deep. Seems a drag bit that is not spring loaded might be better so you can control the depth of cut and cut slightly deeper. First tried with a 0.015 depth of cut as suggested by someone. Will try it again with a 0.060 depth of cut to give more pressure and see if that helps.

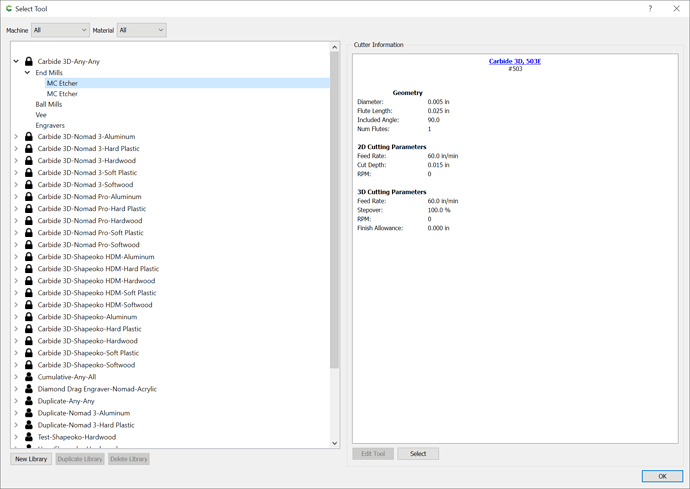

I have 0.004 set for the diameter of the MC Etcher Bit

That looks pretty darn good from where I’m standing.

also the pressure is adjustable with the set screw from the back

That’s a great idea. I didn’t think of tightning the screw to increase the pressure. That may give me a little deeper cut

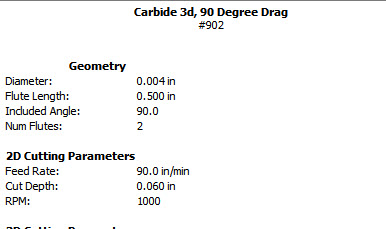

Also, If someone from Carbide3D could provide the actual Diameter of cut of the 90 and 120 degree bit that might help. I could try that instead of using 0.004 depth of cut

I don’t have any way to measure it but tightening the set sew screw seems to significantly increase the pressure on the bit. Thanks for the tip.

The diameter of the cut of the MC Etchers will vary depending on the material being cut, and the pressure applied, and the depth to which one pushes it.

We have added them as tools in the new CC614 beta:

Tried a second pass on the etch design in Granite with increased spring tension on the cutter. Pretty happy with the results but it seems straight lines on the design etch a little deeper than curved portions. Would like the curved portions to be a little deeper also. Maybe increase the spring tension a little more would help. Or could try double cut the curved portion.

How long would you expect the MC Etcher Diamond Drag Bit to last before it needs replaced. I saw somewhere 4 to 5 hours of cutting. The projects i did took about 1 1/2 hours to do and i did 5 of them.

Anyone ever try etching granite with a carbide bit instead of the MC Etcher bit. Like to get a little deeper etch and cant seem to get it with the MC Etcher bit. I tried increasing the spring tension and doing a double cut at 0.015 first cut then 0.030 for the second cut with the same results. Also seems the square around the design comes out a little clearer and deeper even with only one pass at 0.015 depth.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.