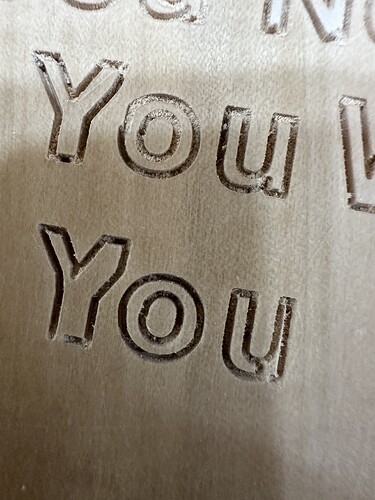

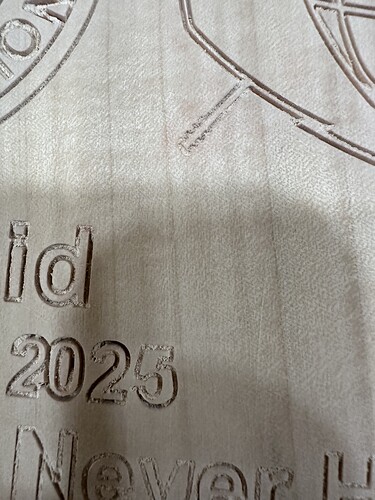

See pics below please. Several letters were switched from atrial to a cartoonish. I also had a problem w/doing 3 shallow passes to avoid waste build up and several lines were triple carved . Thoughts?

That looks mechanical.

Check all your belts, bolts, and other fasteners.

Grab your spindle with the machine on and try to wiggle it. If it wiggles, then you have something loose.

If nothing is loose, then you likely skipped a step or the belt slipped. Which mean you need to lower your speeds and feeds.

As far as the dust in your carving are you using dust collection? Very few jobs that I dont use dust collection but with a #122 (1/32") my dust collection shoe brush can be too long so I dont use the DC foot but I still have the dust collector on. So I dont get good dust extraction but get some. After a tool path finishes I just use my shop vac and clean up the carving. My dust collection is separate from my shop vac. Recutting the chips is not the worst thing but it is also not good. I would likely dull your bits faster.

I agree with @SDGuy that you have a mechanical problem.

Text width is varying. Look close at set screws on the stepper motors controlling the axis aligned with the text width. All text looks to be correct height, eliminating the axis aligned with text height as an issue.

If it’s only width of text in a normal orientation it’s probably the X-axis belt or pulley set screws.

This topic was automatically closed after 30 days. New replies are no longer allowed.