I have an XXL. When I select any of the front 3 rapid positions (SW, S, SE), the cutter travels beyond the front rail of the machine. Is this normal? If the installed bit is close to the spoil board and I select SE, it will run into my bitsetter.

Yes it is normal. The Shapeoko XXL and most likely the other models can cut off the front of the machine. Some people make dovetail and finger joints by making a holding jig that is vertical and hold pieces of wood and let the Shapeoko cut these joints as well as a few other things. So it is normal that the front positions go over the edge. Plus these are good positions to change bits if you dont have the BitSetter.

… and, that really is why you are in control of the process. ![]()

As an example for another tool, if you set the fence on a table saw where it covers the throat plate and raise the blade, you might expect some interference. ![]()

The rapid position points should be over the MDF baseplate of the machine.

When you home, how far is your gantry from the rear plate?

Have you calibrated for belt stretch?

Which version of Carbide Motion are you using?

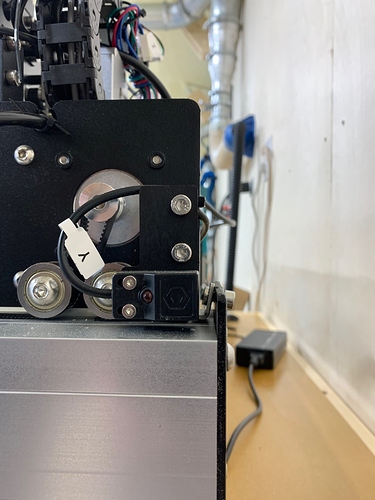

When homed, gantry is about 1/4" from rear plate (measured from homing switch). See attached.

I have not calibrated for belt stretch. It is a brand new build. The issue came up as I was setting up for a supplementary wasteboard hole pattern.

CM version is build 513.

If you are going to make a spoil board remember that the flattening of a spoil board cannot all the way to the back because of the offset of the router position. So make a spoil board that is short enough to be flattened complely at the back otherwise you will have a ridge. The ridge does not hurt anything unless you want put a longer piece that sticks out the back because the material will not lay flat on the spoil board and slope to the front. Additionally you can drill holes your new spoil board near the corners and lay the spoil board on the base board and mark your positions with the drill bit. Then you can get some brass inserts and drill the holes and insert the brass inserts. With the brass inserts you buy flat head screws and be sure to make the recess deep enough so when you flatten in the future your cutter does not hit the screw heads. You can countersink pretty deep just make sure it is deep enough to avoid hitting them when flattening.

This topic was automatically closed after 30 days. New replies are no longer allowed.