I cut a sign this weekend that was double sided and had 3 tool changes per side. I zeroed out each time I ran a step, but when I went to use the rapid return X, Y, it was not returning to the exact place. Once it was 2” off the Y axis. I had problems on the last pass with my letters having an uneven pocket cut, too. Not sure it’s related but I’d like to fix the problems.

Hi @Eileenedwd,

How much off was it when you used the return to XY on average, and did you happen to power cycle the machine between the time you set the zero, and the time you tried returning to it ?

Small fractions of an inch of repeatability offset are not unheard of on a machine that is quite mechanically sound, but 2" is a completely different story, and is likely either due to something mechanical (pulley slipping on the motor shafts ? unlikely on Y axis though), or possibly losing steps due to a collision of the gantry/router against a side of the machine, or to inadequate cutting parameters during the previous cut.

I’m afraid the only way to tell will be for you to share a lot more details about that project you made, including pics if possible, and a very detailed log of each action you took until the problem happened.

Julien,

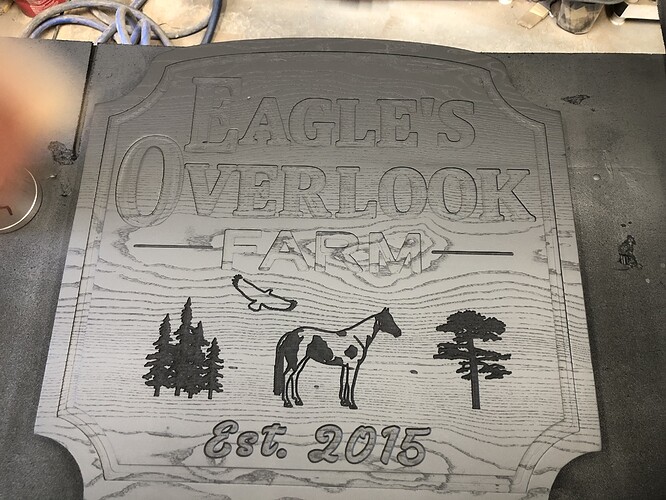

Thank you for responding. I’ve since started painting but here is the sign. It’s double sided so it has the same cut on the other side.

I have

I ran the same gcode for both sides for the first two tools, and the last tool was a different file as it had the additional step of cutting out the sign.

I can describe each tool path or do you want to see screen shots? I’m using V-Carve Pro.

Thanks, Dawn

So about that issue of not being able to return to X0,Y0 did you end up re-doing the zeroing procedure until it was ok, to complete that cut successfully ?

About the uneven pocket bottom, if you used two different tools for those pockets it could be a slight Z offset between the pass with the first tool and the pass with the second tool, and sometimes this is due to sub-optimal workholding (e.g. the stock moving/flexing a bit, and not flexing quite the same during the first pass and the second pass). The best would be to do a test run with a simple pocket and see if you can replicate the issue (you would then be in a better position to investigate why it happens)

For the returns to zero, I manually reset it each time it was off. Fortunately the X axis stayed the same, it was just the Y.

The pocket cut going uneven was the last cut on the second side. I only used 1 tool for it. Would it help do do a cleanup pass afterwards to correct this?

I don’t think it was movement in the piece. I had two cuts before the pocket that were perfect. And the movement seems to get worse as the cutting progressed. I cleaned the collet before I started that side, it not before that cut. Ironically the cutout, which was the last step, had no issues. I seem to have more problems with pocket cuts and V carving being uneven.

This topic was automatically closed after 30 days. New replies are no longer allowed.