@mikep posted these up the other day. I’m going to order these next purchase from Rockler:

Most of what I do on the CNC is repetitive set ups or referencing off the same location of the workpiece . With T-track, it is difficult to reliably repeat setups, and I experienced fences moving with some of the forces of machining producing errors.

The hold downs were also higher profile than what I have now.

The dowels are what helps the repeatability on the wasteboard. The dowels hold the fences and wedges, screws hold the fences, but are not required. I also use hold downs, but the head of the screw only projects above the hold down, so it is lower profile than T-bolts in T-track. Low profile connector bolts are also available, but I have not had a need to change out the pan head screws for the lower profile screws. I used 8mm x 30mm fluted dowels, as that’s what I had on hand from cabinet making, and they work well for holding the fences and wedges. If I need to double side machine, I place 8mm reference holes which correlate to the offset from the fence on the wasteboard, machine the first side, then inert dowels, flip, and machine side 2.

With homing switches, you can set different WCS coordinates for common setups. I reserve G54 for manual zero, G55 for my typical reference, and G59 for the front extension added on to provide full 33x33 cutting area.

First image is prior to XXL upgrade and previous typical dust shoe design.

Second image XXL upgrade with two wedges holding panel for job

Third image showing layout of alternating 1/4-20 threaded inserts and 8mm dowel holes

It is a great point about dowel holes for consistent placement of fences and stock. I guess I don’t run into that much because my projects are mostly one-offs, and I use the Triquetra touch probe to locate the corner of the stock and set XYZ each tool change – if I even need better accuracy than the old eyeball version 1.0. I don’t really use Shapeoko as a precision machine the way many others do – I have the much less fussy Nomad for that.

As usual it really depends on your particular project needs/wants.

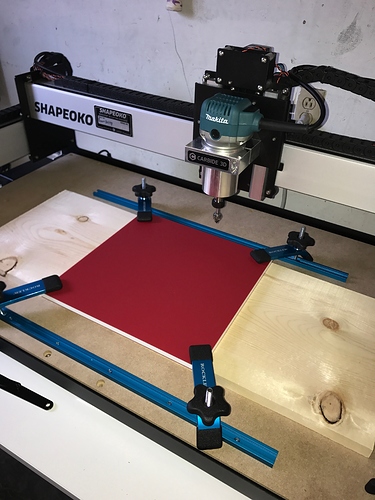

I put Rockler T-Track on my XL this week. I haven’t used it yet though. Like you I’ve gotten as far as Hello World. I was thinking of doing threaded insert grid, but decided that my very first project should not be on the spoil board itself. For the T-Track I drilled pilot holes and then I used #6 wood screws to hold the T-track down. The picture shows the large Rockler Clamps, but I have the Mini Clamps too. Eventually I want to sink the track into the spoil board, but I like @mpfreivald set up too.

I’ve tried them all, mostly.

I find i always like what I don’t have at the moment. LOL

Remember to know your safe retract height, and put it in your CAM.

You can mark where your clamps will be, then run above your table to make double sure you won’t hit them.

I get in a hurry, and keep too low of retract height to save time, but when merging toolpaths, they don’t always behave the same as in the simulations.

My last crash ripped 2 threaded inserts out of the table, and chewed up steel clamp, And broke a V wheel.

I had to buy the maintenance kit for that one

Better to get that ahead of time, as well. But they do ship fast

I started with the Rockler tracks screwed directly to the waste board since the screw holes were pretty minor damage compared to other things that happen. One carbide-to-aluminum strike and I pretty much stopped using it. Even the small clamps have a pretty high profile.

90% of the time I end up using the masking tape/CA glue method

I also installed the Winston Moy wasteboard and use the Carbide (tutorial) clamps. I have the hardware to reuse the Rockler clamps but they’re so big I never did that