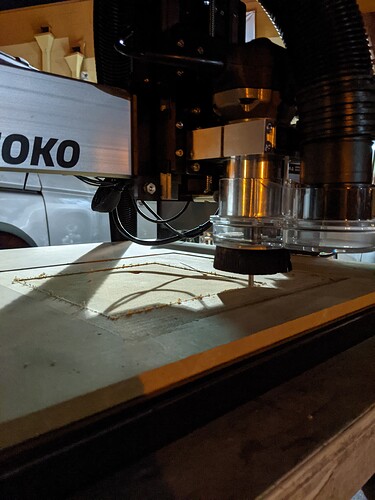

So I did some test runs with my Shapeoko 3. Everything seems fine for the most part, but the depth of cut had me confused. I have the max cut depth set to 0.0394 inches, with a #210 mill. The first pocket I machined is about 0.065 inches deep, but the 2nd pocket is 0.042 inches deep. Also, it started machining the 2nd pocket at the bottom of the 1st pocket for some reason, even though I zeroed Z-axis on the top most surface of the material. Material is MDF.

For this reason, I’m not sure I have the Bitsetter properly secured. I cannot have it sit on the frame as low as possible, because my setup doesn’t have enough depth to allow it. I suspect my mounting screws are not secured enough, but I would like your guys’ feedback as well.