Thank you. Both posts are helpful. I really need to get some time to just play around with the software and do some trial and error runs. I stay pretty busy from Nov until about April making plaques for Euro mounts. I have 3 taxidermists that I cut plaques for. Therefore, 90% of my cutting has been keyholes and contours.

I have a MillRight M3 machine running a DeWalt 611 which I think is excellent. I purchased PreciseBits.com ER collets for the dewalt and there is practically zero runout. This is important for fine detail work I do on that machine (like MOP inlays). My SO4XL uses the stock C3d router. I had some small issues with it out of the box, but support was fast at helping get it fine tuned with required parts etc. Brushes went out once after a heavy job, but it has not been a show stopper to any extent. I bought an extra Dewalt 611 for my SO4XL but have not swapped it out as of yet. I may not either. The nice thing on the C3d router is you can use two wrenched to tighten the collet which is a huge plus when cutting guitar bodies. The Dewalt only has the button as far as I recall and I am concerned if the collets would tighten up enough to use a 3” long bit through 1.75” stock. Though the ER style collets on the Dewalt (purchased separately) do not require near as much torque as the stock C3d collets. I’m on the fence of what my next move will be. DeWalt or ER version of the C3d router.

The problem I have is that since starting to use my Pro XXl in June, Ive had one C3D router smoke the bearings and the replacement one is staring to squeal and its only been in the cnc for about 7 or 8 hours of run time. I used my makita between and due to the dial not locking into place (Ridiculous design) it would jump speeds. C3D is great for their support, no doubt. I just want to be able to run without having to continuously replace my router.

Just wondering and haven’t seen it posted yet, but what material, bit and feeds and speeds are you using? Just a thought, but if your settings are not close, you could be pushing the router (or bearings) too hard. IE running a low RPM and a high feed rate through oak, iron wood, ipe or similar.

The one nice thing about all these routers with an adjustable rpm, is you can adjust on the fly. If the machine is working to hard, you can increase rpm or if the chips are more like dust, slow it down etc.

When cutting Red Oak (which is what I mainly cut), I’m running a 1/4 inch cutter @ around 17,000 rpm, .095 inch cut depth and 30-35 ipm. I always stay right at the cnc when it’s running because I have noticed a few times where I could tell it was hitting harder areas in the wood or even from board to board. That way I can hit the decrease feed on the computer. I never push the machine hard. That’s why I dont understand the issues with the routers.

If the speed and feed sound wrong for cutting red Red Oak, I am very open to suggestions. My DOC for a 1/4" spiral upcut is at .095 in.

If you are using a spiral upcut end mill, then those numbers do not seem out of line.

I based it off of what the cnc at work runs at with minus the depth of cut. The guy running the cnc at work is way off on his feeds and speeds. You can tell by listening to it. He runs a half inch compression through 3/4 mel at full depth of cut (3/4 in) at 750 inch per minute. And can’t understand why he throws parts left and right. Can’t remember what the rmp is set at but at that fast of a feed, I don’t think it really matters. lol

I should add that the 1/4" is about the only bit he runs at a somewhat normal feed and speed. I actually had discussed some of this with the programmer.

I like C3d and the support they give. However the C3D router is a clone of a Makita which is not the best of the best. So cloning a less than perfect router results in what you are experiencing. Do Dewalt routers have problems, yes, but you hardly ever see anyone complain about a Dewalt router on the forum. In the early days of the SO3 the Dewalt was offered and they included a spacer to accommodate a Makita. Now the Dewalt is not as popular as it once was. I have been on the forum for a long time and I cannot recall any complaints about Dewalt. That is not to say there are not any but I have seen a lot of complaints about the C3D router. Is the complaints because it is sold with the C3d machines and considered as part of the Shapeoko or is just because they are not the best router you could get. I have the Dewalt and like it so much I bought a second one with the plunge kit for general shop trim router use. The Dewalt 611 will not replace a larger 2-3 HP router but for use as a trim router it is pretty good. I have never needed to put in my second router because the one in the Shapeoko has never broken down.

So you have to evaluate your needs and go with what causes you the least amount of headaches. My Shapeoko came with the Dewalt but if I had headaches caused by it I would replace it. For the modern C3D machines the only choices are the Makita or the C3D router which is a copy of the Makita. So which do you think is the better router, the Makita or a cheaper copy of it. If you already have a 66MM mount and do not want to buy the 69MM mount required for the Dewalt then get a Makita. If your machining is business critical then have two. If you are just a hobby machine then put up with the down time or go up to a full spindle. The choices are simple but the decision may not be so simple depending on how critical your machine is and your budget.

The Pro XXL is much more robust than my SO3 so maybe it is time to move up to a spindle that can take better advantage of the capabilities of the Pro machine.

The issue I had with running the Makita is that the dial for the speed does not lock in place. I ran into the issue of it changing speeds on its own. And it was usually a big drop in rpms. I have had several people tell me they liked the Dewalt and haven’t heard much of problems. I plan on going to a spindle but it’s not in the budget right now. (according to the wife). I did upgrade to the HDZ at the purchase of my cnc in anticipation of going to a spindle eventually.

Ha, I also have a second Dewalt (and plunge) for general routing besides the one I bought to replace the C3d router. So I have two besides the one in the smaller CNC. I really like them. I may end up buying the 69mm mount and changing it over. Do you use the precise bits.com ER collets? According to Precisebits.com they do not recommend the Makita at all. But they also don’t make any parts for them, so it may be just business.

Kelly, just a few other things to look at before installing a new router.

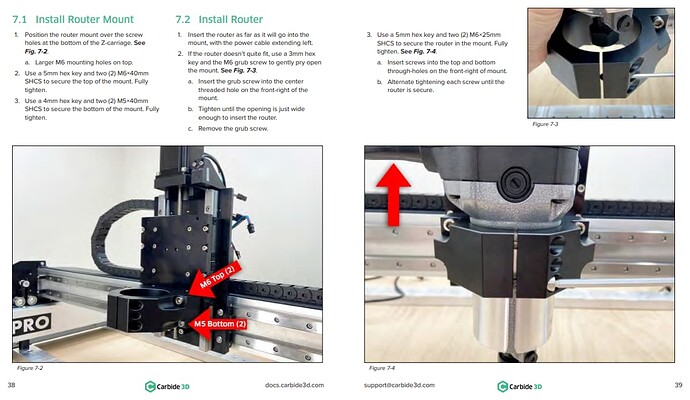

In step 1 of 7.2, they say to insert the router as far as it will go. Well, there is not a shoulder on the router housing to sit flat on the router mounting block. I would suggest inserting the router as far as it will go then lifting it up 1/16". This will insure the mounting block bore comes in full contact with the machined portion of the router housing. On a Dewalt, you may have to lift it a bit more due to the amount of radius they machined on the router housing. In any case, you want a cylinder to cylinder contact only.

In 7.2 Step 2-C. Remove the Grub screw. This is critical and understated.If you tightened the two (2) M6×25mm SHCS as seen in step 3 of 7.2, you may not be clamped on your router housing securely and damage may have been caused to the router mounting block.

In 7.2 Step 3. They say “Fully Tighten”. I know not everyone has a torque wrench in the tool box but it would be great to have a torque spec here. If over tightened, it could crush the router housing enough to cause bearing issues.

As you tighten the router mounting screws, compression forces go toward the center. The hoop strength of the router housing is a lot less than those two screws can apply.

I hope this helps.

This topic was automatically closed after 30 days. New replies are no longer allowed.