My project is not cutting in the program location. I have reset all the zeros and resaved the tool paths and it still is cutting far from the setup.

Please review:

https://carbide3d.com/hub/courses/running-shapeoko/movements-zeroing/

and

https://carbide3d.com/hub/courses/create/job-setup/

If you still have difficulty, upload your .c2d file and let us know step-by-step how you are securing your stock and setting zero relative to it and upload photos showing the machine at the zero position (or specified offset from there) and a screengrab showing what Carbide Motion is showing.

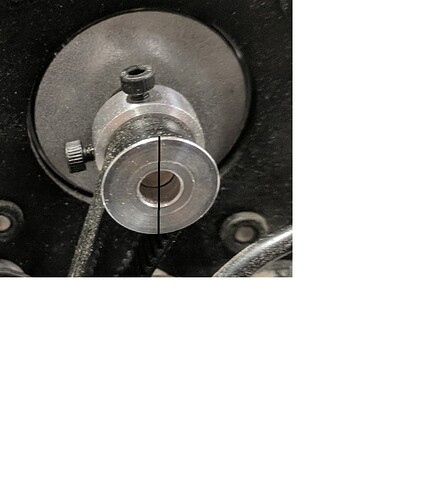

There are two possible issues to look at. First is your setup does it match where the machine is cutting. Sometimes we think we have set one position but really set another. The second would be possibly a loose v-wheel or other obstruction causing the SO3 to miss steps. Things like a drag chain, dust collection hose or the stepper motor pulleys are loose. Each stepper motor on an SO3 has two set screws. One of the set screws is positioned over a flat on the stepper motor. Some people have the stepper motor pulleys come loose and the SO3 moves randomly. If you have check your pullyes put a black magic marker across the end of the pulley over the center of the stepper motor shaft. That gives you a quick visual reference if a pulley has come loose.

This topic was automatically closed after 30 days. New replies are no longer allowed.