I’d suggest cutting the extrusions SQUARE would not significantly raise the price point and remove many complaints.

I gotta say, I love (love) my S3XXL. I do all sorts of things on it, cutting and lasering. I know there are a lot of options and lots of ways to DIY in the CNC world. What Carbide3D provided me was a way to start doing things immediately with capable if not advanced software and learning learning learning about the CNC world. You can always improve/upgrade or find some fault. What Carbide has done is to find the sweet spot of providing a low-cost yet very capable machine that’s ready to run as soon as you put it together, easy to use software (which can also sometimes be annoying and limited,but still great at what it’s intended to do) and just a reliable and repeatable machine. It’s just so great to have this tool for so many things. It’s adaptable, reliable, powerful and easy to use. And it’s ready for DIY upgrades! I really can’t imagine a better option for the price.

I don’t post often, typically pretty busy, but saw this post and just wanted to add that I went through some of the decision gates you talked about - my advice: don’t worry about doing something totally optimal at the outset; the upgrades you’ll do you can’t even imagine now, you have to get something and start using it to really know what you’d want to improve. Many of your imagined improvements will go away, new ones will reveal themselves to you. And, you’re going to spend a lot more than you think you are, no matter which way you go.

I know that eventually I’ll do many upgrades beyond what I’ve been able to do by now, but I’m super happy with the experience in making the stuff I have done to-date with the stock S3. Good stuff, relatively low cost and good support, can’t go wrong.

I have a Shark Pro HD that I hate. The Shark has propriety licenses and does not come with any CAD/CAM software. You can buy Vetric for a discount but you have to buy it.

I bought a used Shapeoko XXL and just love it. The Carbide Create and Carbide Motion software is free and is quite useful for what I do. As you get more advanced you may want to move up to different software but most people can use the CC and CM forever.

I have given this advise to new or prospective buyers.

- Have a purpose in mind for the machine. If you buy one and then try to find a purpose you may never really get much use out of it.

- The CNC Machine is only the first 1/3 of your cost. The second third is investing in bits, tools to prep and finish your projects.

- The software to feed your machine if you choose to go with pay software can be 1/3 of your overall budget.

- Most importantly is the time it will take to learn how to effectively use and product something useful with the CNC Router. There is a learning curve that is quite steep if you do not have a background in design. There is also a steep learning curve in learning how to operate the CNC Router itself.

i do not want to discourage you but if you are not ready to make a financial and time commitment this hobby may not be for you. There are countless CNC Routers sitting in garages and basements languishing in obscurity because the commitment to learn how to use the machine was not there.

Lastly before I retired I was in the high tech industry. Many of my colleges would chase the latest and greatest usually to find themselves on the bleeding edge of technology. i emphasize the Bleeding part of my last statement. Later in my career I did not even want to customize the desktop or spend countless hours finding cute little applications to waste my time on. I just wanted to turn my computer on, use it then turn it off at the end of the day. Maybe that is why I like the Shapeoko, you just turn it on, create and turn it off. There is maintenance to do on any machine but my Shapeoko is like the Energizer Bunny, it just keeps going and going.

Looking at some posts here, I have a suggestion for a small update to the Shapeoko: Provide standard threaded mounting holes on the spindle mount to attach accessories like laser, air nozzles for chip evacuation, pen and vinyl cutters, etc. These accessories need to be mounted on the spindle or mount so they can go up and down. The issue is that since there are no standard mounting points, unless it fits in a collet like a diamond drag bit, one need to figure out some way of mounting the device. Having standard mounting holes would make it easier for producing standard attachments. This should be fairly easy to produce at the factory at a relatively low cost.

same would go for the Nomad.

generic holes they determine to be best suited for most add-ons and a basic drawing showing such. much like the pdf of the nomad table.

Hey Paul, I asked first!  Of course the Nomad too… but after.

Of course the Nomad too… but after.

Agreed! There are several holes you can use in a pinch on the Nomad but all of them are a compromise one way or the other. None of them are easy to use.

just one more input: you ain’t gonna figure out the best upgrades to your rig ahead of receiving it and spending some time on it. It just takes time and experience, so just buy the stock thing and start in. I’m looking forward to some upgrades to be able to do aluminum with a mister cooler and more 3d stuff with coolant recirculation etc. But in the meantime, it’s so great to just throw some stock on the table and cut some 2d or 2.5d stuff. Of all my tools, this is by far my favorite.

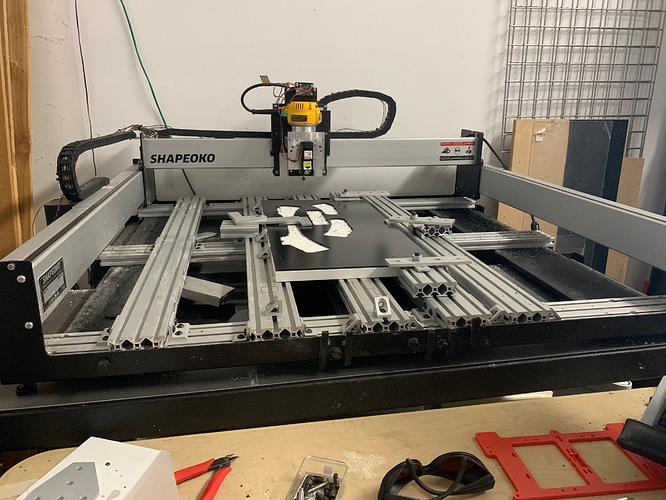

not claiming these are the best hold-down techniques… haha.

that is a neat set up! I assume it is pretty darn rigid, too!

Hello!

Do someone could add to the “other g code senders that have more complicated probing macros available”. Which one? I do not see probe macros in UGS.

I’m interested.

The answer is “CNCjs + Neil’s macro magic”. Search for posts by @neilferreri with “CNCjs” and “macro” keywords and you will find a treasure trove of macro goodness !

n.b. are you by any chance a fellow French shapeokoer ?

Waou thanks! Yes I’m a Canadian French “shapeokoer” .

Where are you from? My Shapeoko is in the Laurentians

I’m in Quebec city!

And I’m too Canadian French, My Nomad Pro is in Montreal city…

thanks! not sure how rigid it is, haven’t really tested that - but the hold-down options are super convenient!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.